Why choose Markem-Imaje?

Intelligent solutions to connect products and protect brands

Whatever the size of your business, from startups and local producers to large global manufacturers, all share the common goals of optimizing operations, compliance with local and international regulations and standards, brand protection, improving ESG metrics and making customers satisfied. Our solutions unlock the power of intelligence in codes to help our customers achieve all of the above and more, end-to-end throughout their supply chain.

Reduce Waste | Drive Efficiency | Achieve Compliance | Track & Trace | Detect Threats | Engage Consumers

A solutions one-stop-shop...

with a complete portfolio of coding technologies, packaging intelligence software, connected product and maintenance services and supplies.

A worldwide network...

encompassing 41 offices in 28 countries, 280 local distribution partners and a network of +2,500 dedicated OEMs.

Prize-winning innovation...

including a European Excellence Award in 2020 and the PPMA Innovative Packaging Machinery Award in 2022 combined with decades-long market-changing CIJ and TTO technology. Many years at the forefront of laser, Print and Apply and Drop-on-Demand development.

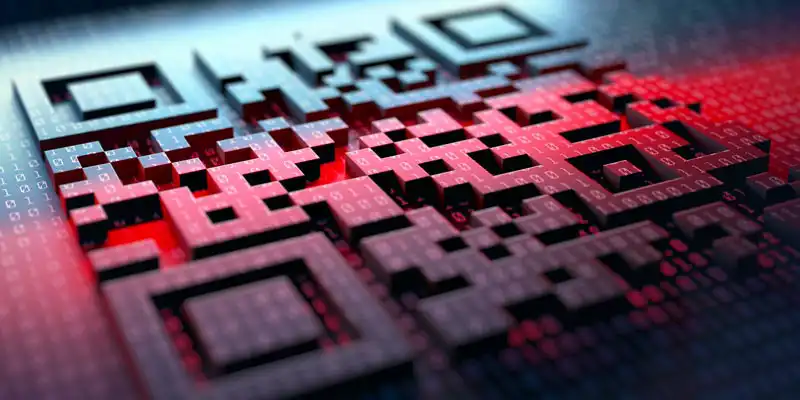

Unique CoLOS® software...

allowing automized verification, ERP integration, serialization, and traceability across the supply chain to facilitate compliance with the latest international regulations and GS1 standards.

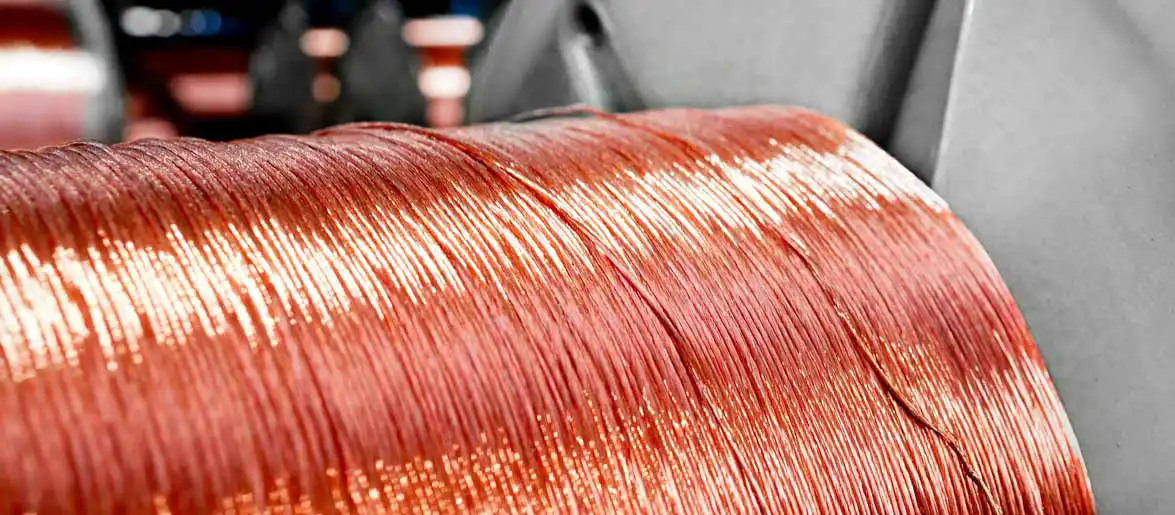

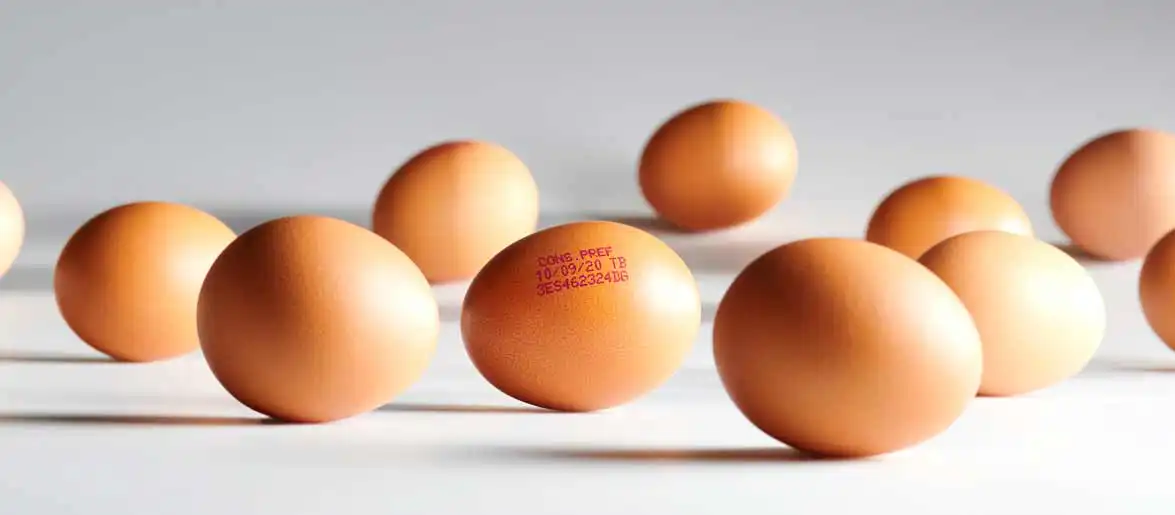

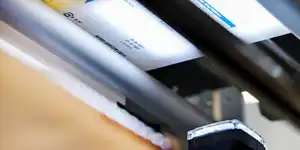

State-of-the-art printing technology...

for highly durable and legible codes eg. 1D, 2D dynamic barcodes and graphics that comply with regulatory requirements, printed on virtually any surface or shape.

Increased production uptime...

by both boosting the time between services and simplifying maintenance duties with our innovative and modular designs.

Possibility to reduce harmful VOC emissions...

by up to 60% using our MEK-free ink portfolio and consumables use by up to 40%.

BRCGS Packaging Materials Global Standard grade A Certification...

benchmark recognized by the Global Food Safety Initiative (GFSI).

AI-powered Virtual Assistant and Connected Printer Services...

for trouble-free operations and quick recovery.

Product identification, packaging intelligence, and connected product solutions empower you to:

- Make production lines more efficient and reliable

- Achieve critical sustainability and compliance objectives

- Connect, protect, and track products across the supply chain

- Strengthen consumer confidence in their brands

See what our customers recently say about our industrial solutions

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions