Coding on food offers

100% safe and edible inks, compliant with local and national regulations.

YOUR CHALLENGES

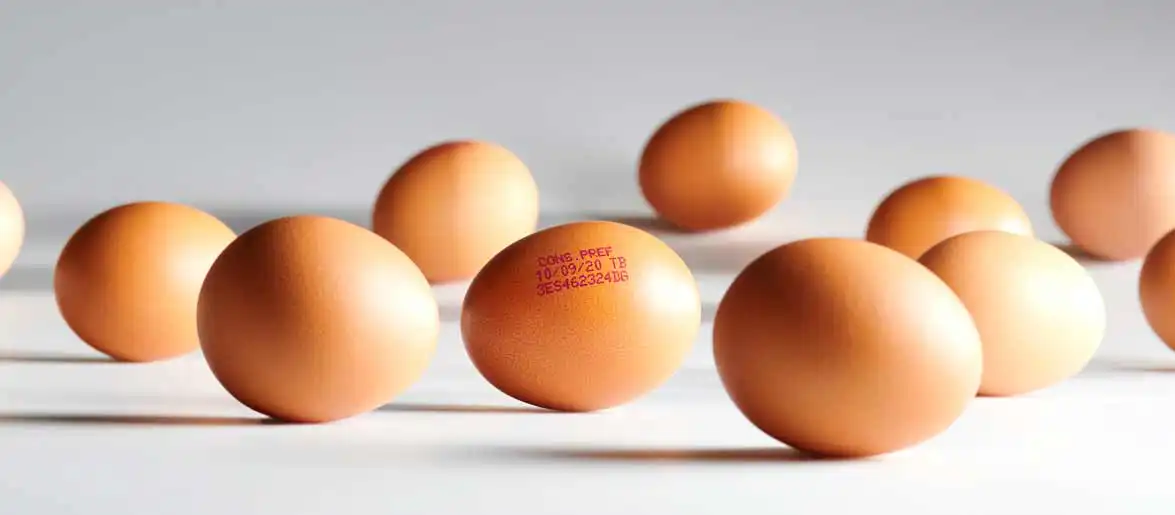

Coding on food is a challenging application because of the fragility of foods that are printed on, like eggs, and the fact that ink comes into contact with foodstuffs, whether directly or indirectly. This means that the ink must be completely food grade compliant and must not alter the flavor or taste of the food in any way. One of the most in-demand coding on food applications in markets including the EU, UK and Australia is egg coding which is compulsory for traceability purposes and providing best-before dates.

Using inks that come into direct contact with food, known as food-grade inks, can be complex because numerous regulations exist relating directly to the raw materials that make up the inks. Printing on food may seem challenging, yet, in addition to reducing costs, the application offers benefits from greater flexibility to late-stage customization which can help brands differentiate themselves in a crowded marketplace.

Producers are also facing demands to code at ever higher production speeds and pack rates with a need to maintain consistently excellent quality. For applications like egg coding, each individual egg is marked and batches may contain thousands of units of different sizes, the demand to mark consistently, without blurring or distortion, and at high speed, is only suited to the most compliant and high-performance coding hardware and consumables.

With decades of experience across the food production sector, you can trust Markem-Imaje to provide the optimum solution to coding on food.

Fortunately, we can help you find the ideal coding on food solution to meet your needs.

OUR SOLUTIONS

Continuous inkjet (CIJ printer) is the main technology for coding on food, both for direct food contact printing and indirect food contact coding. Markem-Imaje has a full range of specially-developed proprietary inks that are either fully compliant i.e. food grade inks.

Markem-Imaje proprietary CIJ inks, specifically designed and approved for direct food contact, are available in pink or blue, the color chosen depending on the region and, if for eggs, then whether they are white or brown. CIJ can print up to four lines of text and one logo per egg, allowing it to fit all necessary information and brand marketing if desired. Thanks to specific communications protocols, printers can be easily integrated with a variety of egg graders.

With more than four decades of experience in innovation in CIJ and consumables specially made for the food production and processing sector, Markem-Imaje can provide not only compliant coders and inks but also guidance through regulations. Indeed, we help manufacturers with traceability essential for regulations, like the US FDA’s FSMA, and maximize your uptime and overall equipment effectiveness (OEE).

Please note, if you are looking for flexible film packaging coding solutions, please visit our dedicated flexible packaging printing webpage.

If you are looking for primary paper packaging printing including labels, please visit our dedicated paperboard priting webpage.

Simply leave your e-mail address in the form of this page to be contacted by one of our experts who can provide detailed information and can help you find the best solution for your coding on food needs.

What our customers say about our solutions

We are cutting our operating costs by at least 20%. The 9450 allows us to change consumables without stopping the printers and reduces the number of printhead cleaning operations. In addition, the smart ink cartridges help reduce human error and optimize everyday tasks.

Mario Carbonell, Technical Manager, at Huevos Guillén Group

Quick links — Jump to the right section directly!

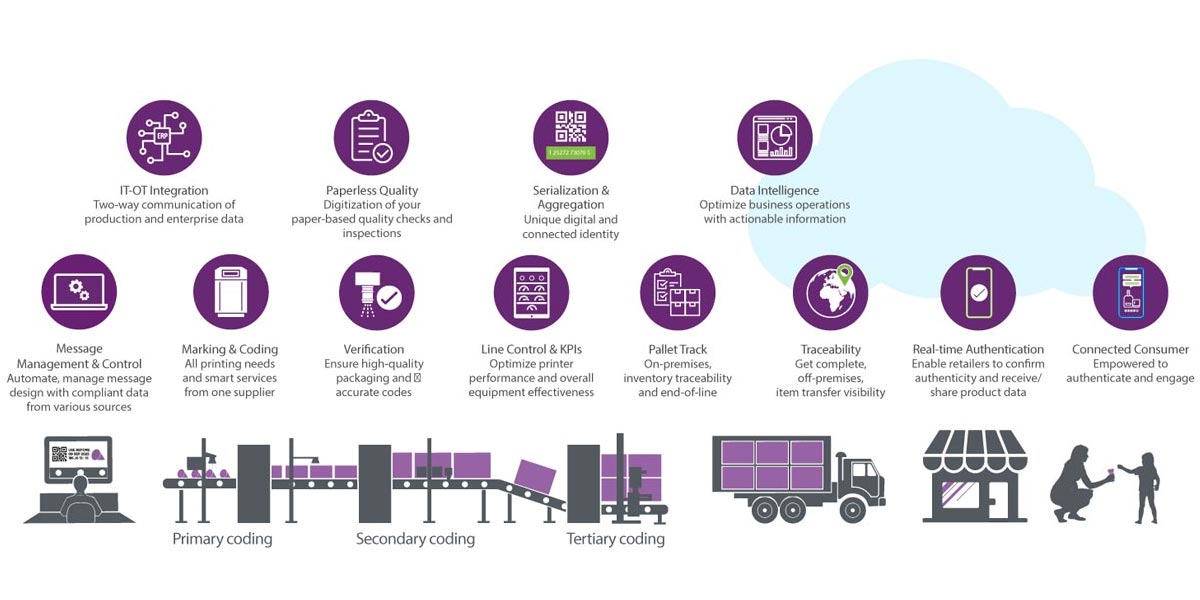

Connected Packaging and Packaging Intelligence software

Our Packaging Intelligence solutions combine our proven coding and marking expertise with our experience to deliver complete turnkey solutions for achieving the maximum packaging line efficiency, trouble-free data management, and supply chain traceability all the way to the consumer’s hands. CoLOS® will significantly enhance your productivity and quality control while also addressing the challenges of waste and costs in an ever-changing manufacturing environment, creating a smarter business. Looking for a partner to develop your product’s digital roadmap? Markem-Imaje end-to-end solutions include leading solutions for supply chain traceability and authentication through our Systech brand and an ultimate consumer engagement experience with Blue Bite.

With more than four decades of experience in Continuous Inkjet (CIJ printer) innovation, Markem-Imaje offers a line of continuous inkjet inks together with a line o f wax-based, edible hot-melt inks that are FDA, EU, and kosher compliant. For incidental food contact with packaging, a line of inks is also available. Designed for maximum uptime and ease-of-use, our CIJ range simplifies daily activities and makes your coding process seamless.

Markem-Imaje 9330

CIJ printer designed for light to medium duty production lines, the 9330 series offers versatility, cost-effectiveness and longevity, covering all your basic coding needs, with the capacity to print for more than 8,000 hours non-stop.

View Markem-Imaje 9330Markem-Imaje 9450

CIJ printer primed for medium to heavy production loads, the 9450 features Intelli’inks design, making set-up clean and automatic, maximizing your production uptime and OEE. The 9450 coder prints high-resolution codes 20% faster than similar printers of its generation and is specially primed for food-grade printing, egg traceability, and indirect food contact coding.

Markem-Imaje 9750 Expert Series

CIJ printer designed for the most challenging, and fast-food packaging printing operations, the market-first 9750 Expert Series of CIJ printers has been innovated to mark tiny surfaces, deliver 2D coding and only requires one type of coder for dye or pigment prints. Fully stainless, the 9750 Expert and Expert + code at line speeds of up to 120,000 units per hour and are suitable for both direct and indirect food contact coding.

View Markem-Imaje 9750 Ew+Markem-Imaje 9410

CIJ printer suited to medium to heavy production needs, the 9410 prints multi-line codes in various colors while simultaneously optimizing costs and reducing power and consumables consumption to achieve a lower TCO. Suitable for indirect food

contact coding.

Markem-Imaje 9750

CIJ printer designed for medium to heavy-duty production lines, the 9750 is primed for digitalization and traceability with its unique 24-pin interface. The 9750 is also designed to be less environmentally-impactful with its easy-to-use, modular

format, IntelliDesign and consumables-saving function. Suitable for direct food contact and indirect food contact coding.

CIJ Flexible Packaging Consumables

We offer a full range of proprietary inks to match your date coding on food requirements with a full range of compliant food grade and food contact inks including MEK-free options with reduced VOCs, all designed to improve your TCO. Our consumables range includes blue and pink food grade inks e.g. for egg coding on both white and brown shells, thermochromic inks that change color upon temperature change and resist sterilization, as well as high-adhesion (smudge-proof) and condensation-resistant inks, ideal for marking date codes on food.

2D codes have already become an indispensable method of connecting your products to the Internet, facilitating vast amounts of product data and customization possibilities. They are also simultaneously becoming essential to comply with new regulations and standards, especially concerning traceability, including for the GS1 Digital Link, Digital Product Passport, and the US FDA’s FSMA regulations. The advantages of 2D codes for boosting brand loyalty through the supply chain are unrivaled. The possibilities for promoting sustainability efforts, packaging design efficiencies, and retail process optimization are enviable.

With the GS1 set to begin phasing out 1D barcodes in favor of 2D codes like the QR and DataMatrix from 2027, at Markem-Imaje, we have GS1 Digital Link-compliant 2D codes at the heart of our innovations from our coding hardware to software solutions supporting leading brands and retailers around the world to define and implement their connected product roadmap. Connect with us to talk to an expert or read more on our 2D solutions dedicated page

Simply leave your e-mail address in the form to be contacted by one of our experts who can provide detailed information and can help you find the best solution for coding on food.

You may also be interested in discovering more about...

Consumables and supplies

Find our genuine CIJ, DOD, TIJ, and Touch Dry Hot melt inks adapted to each marking need:

Inks and additives.

Software

Find options to digitalize your packaging operations easily:

CoLOS software solutions.

Solutions

Find our Packaging Intelligence Solution to enhance and achieve traceability:

Traceability solutions.

Find industry hot topics that benefit from using 2D barcodes for connected products:

Connected and compliant 2D barcodes.

Find out our Code and Packaging solutions.

Find out our Product distribution and compliance solutions.