Late-stage customization gets personal with new automated print look-up

Coding and marking equipment for direct printing has proven an extremely reliable, low-maintenance and cost-effective way to apply text, logos, and barcodes to corrugated containers and other Traded Unit secondary packages. In addition to other advances in print quality, resolution, ink-clogging prevention and reliability, a new feature in our 1000 Series TIJ (Thermal Inkjet) printer brings even greater efficiency: TU (Traded Unit) Look-up.

TU Look-up is a way to meet new data-heavy challenges such as GS1-compliant barcodes, store-brand personalization, and smarter automation. In turn, it can help you increase line throughput and improve traceability from the end of your line through warehousing and distribution.

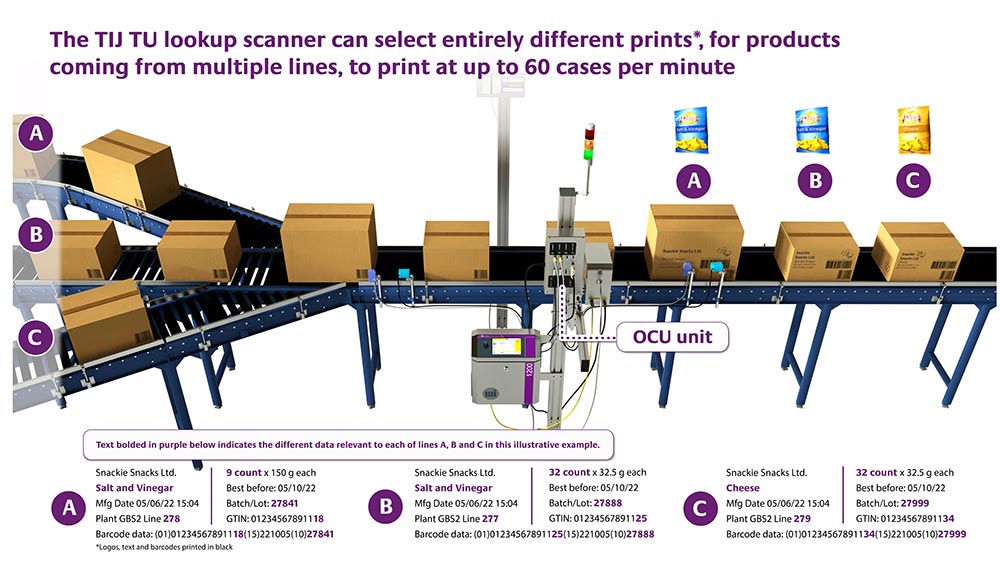

This new feature makes it easier and faster to get printing, whether you have frequent job changes or even multiple SKUs (Stock Keeping Units) feeding to a single printer. It works on corrugate, plastic, metal, or wood, with the package coming to the unit only needing to have a pre-printed barcode identifying its specific SKU.

How does it work?

Take the case of a packed corrugated box. As it approaches the printer, the scanner will scan the pre-printed barcode identifying the SKU and send the associated data to the onboard controller. The controller then looks up the SKU in its data table, automatically identifies all the information fields and printheads needed for the job, and the printer runs the job. For quality assurance, you can add up to two verification scanners and an automatic rejection feature.

The new technology allows you to add value to customers’ packaging from barcode data to text and artwork, for example:

- A laundry detergent brand or co-packer that does private labeling can print, for instance, boxes for store brands that include custom logos and text, including any required GTINs (Global Trade Item Numbers).

- A potato chip company may label three varieties of chips, such as one for salt & vinegar, one for nacho cheese and another for sour cream & onion. In this case, personalization might include a logo as well as a GTIN.

- A produce company might be running three lines to package carrots, apples, and bananas. If the company wants to feed all three to a single printer station, a TU Look-up-enabled printer can handle the job and will automatically “know” if they have different expiry dates specific to each SKU — it is all in the look-up table.

You can now more efficiently print your outer cases with any data, text and decoration to satisfy your customers’ needs as well as meet any regulatory requirements.

TU Look-up solutions

TU Look-up has been available for years in our 5000 Series large character high-resolution piezo inkjet printers. These models work excellent in fast-moving food production, beverage, and pharmaceutical industries. The direct-printing piezo equipment suits extremely high-resolution printing and adhesion for the most demanding supply chain efficiency and traceability requirements.

Now, TU Look-up comes to our 1000 Series TIJ printers which are also used in these industries, and are ideal for case coding, but in lower-volume or intermittent applications. Both models in this series offer high-resolution codes and ease of use and maintenance.

The great benefit is that this is a new, faster way to select jobs, especially when using smaller touchscreen panels with a large quantity of jobs to scroll through. In action, the operator should not need to do any manual input beyond starting the print job.

All of these printers come with a color touchscreen and software that lets you create or import images, control, and manage printing jobs in a graphical dashboard interface and more. They can be used in standalone mode or securely integrated with factory information systems from production lines and databases, or ERP (Enterprise Resource Planning) systems.

Adding TU Look-up to your high-resolution DOD (Drop On Demand) coding operation can make quick work of setup, job look-up and quality control for greater productivity and savings.