Modernize inspection and verification in the food and beverage industry with CoLOS ® AI-based Vision Solution

In the packaging industry, ensuring product quality and compliance with regulations is crucial. However, incorrect labeling, packaging defects, and manual inspection processes can lead to costly recalls, damage brand reputation, and compromise product safety. This is where CoLOS ® Vision solution comes into the picture.

In case of food and beverage manufacturers, despite their impressive scale and success, company packaging operations can be hindered by legacy systems, which ultimately impacts their bottom line. To modernize production and boost productivity, they need to address the pain points of packaging accuracy and throughput, which are usually compromised by human verification and coding errors, resulting in unnecessary waste and costs.

The challenges they face:

- Product recalls due to unreadable, smudged or missing batch numbers and packaging details

- Packaging waste due to coding errors and tedious re-packaging process

- Missed anomalies and defects due to manual inspection and sample verification

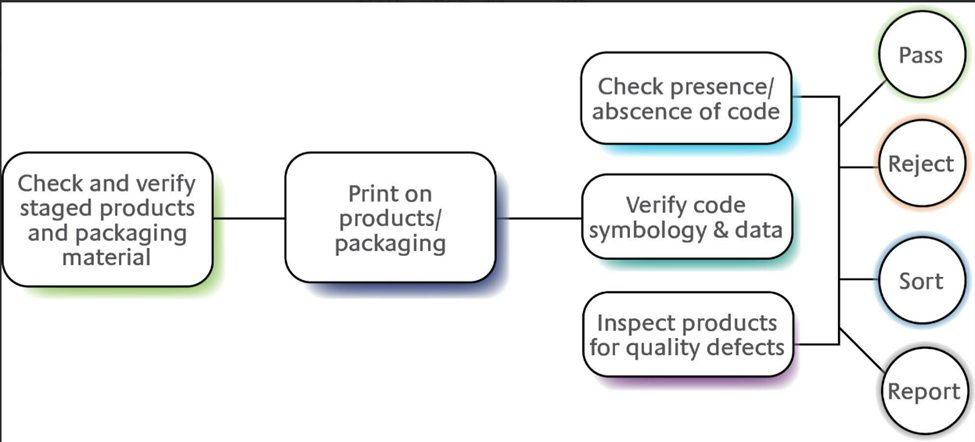

CoLOS ®̥ Vision Solution offers a comprehensive answer to these challenges. By utilizing advanced checking, verification, and inspection methodologies on products and packaging material using Cognex’s AI (Artificial Intelligence) enabled vision systems - In-sight 2800 & In-sight 3800, the Vision Solution ensures accuracy and print quality in real-time. This automated process minimizes waste, rework, and costly recalls, while also reducing compliance risks and regulatory fines.

The AI-based CoLOS ® Vision Solution by Markem-Imaje helps our customers to:

- Check and verify that the correct messages and codes are printed on the product/packaging material every time using advanced OCR (Optical character recognition) technology

- Verify that the message is readable, correctly placed, not tampered/distorted via rule-based vision tools

- Verify correctness of the messages within the1D/2D code

- Inspect the products for defects or deviations to pass/reject them in real-time with AI based edge learning tools

- Generate quality and rejection reports

- Effectively manage all Markem-Imaje printers and vision tools on a single user interface by CoLOS ®̥ software.

The benefits of this solution are numerous. By automating the verification and inspection process, a company can enhance brand protection and promotion, increase production efficiency, and reduce the risk of human errors.

CoLOS ®̥ Vision Solution can verify complex codes, including multi-line text, 2D codes, and more. With its advanced features and functionalities, it provides a robust solution for packaging and coding integrity.

In conclusion, packaging inconsistencies can have far-reaching consequences for companies. CoLOS ®̥ Vision Solution offers a comprehensive answer to these challenges, ensuring packaging integrity, coding integrity and product quality. By automating the verification and inspection process, companies can reduce waste, enhance brand protection, and increase production efficiency.

Learn more about CoLOS ®̥ Vision Solution and how it can benefit your business.