Advanced Code Verification and Product Quality Inspection for the Beverage Industry with CoLOS® Vision Solutions

The beverage industry faces numerous challenges to ensure good packaging quality. With a vast array of product varieties, packaging types, and regulatory compliance requirements, the need for traceability, unique labeling, minimizing waste and downtime demands a robust quality inspection process. Manufacturers must prioritize quality inspection to avoid human errors, reputational damage, and costly recalls.

CoLOS® Vision solution is fully integrated with vision systems from Cognex Corporation to address these pressing challenges faced by the beverage industry today. By leveraging advanced AI-based capabilities in vision systems, our solution enables coding integrity, packaging integrity, and product inspection seamlessly. Our solution allows close integration with the ERP systems and real-time communication capabilities between the IT and OT systems, which helps in trigger-based printing.

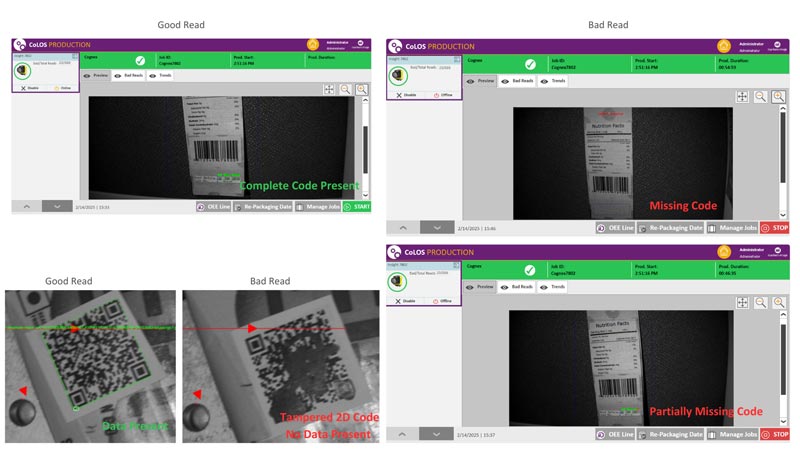

Coding Integrity: Verify product codes, lot number, expiration dates on products, case and pallets to ensure accuracy and compliance.

A beverage manufacturer producing a variety of flavored drinks with different expiration dates and batch numbers would need correct data, date, and lot number to be printed on the correct product. Coding Integrity from CoLOS® Vision solution, powered by Cognex Cameras, uses OCR (optical character recognition) & OCV (optical character verification) tools to attain the highest accuracy. Our solution also verifies that the printed 2D barcode is legible and checks the correctness of the data embedded in 2D barcodes, including GS1 Digital link QR codes, and supports barcode grading. This comprehensive approach ensures that products are accurately coded/labeled, reducing the risk of errors, recalls, and reputational damage.

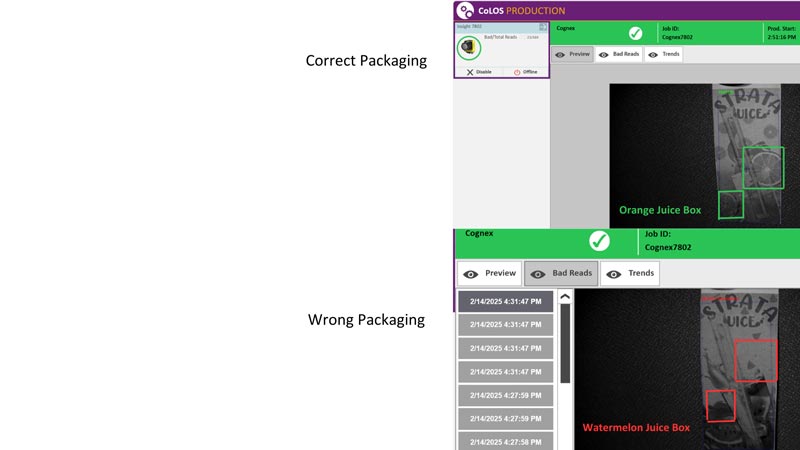

Packaging Integrity: Verify product packaging for design and damage.

Packaging integrity is another essential aspect of quality inspection in the beverage industry. With varied taste and flavor profiles, packaging designs, and sizes, it becomes essential to ensure that each product has the right packaging. Our Vision solution ensures packaging integrity by detecting incorrect packaging, damaged or compromised packaging, and color errors. This enables manufacturers to prevent product mix-ups, meet packaging quality standards, while also reducing waste and guaranteeing retail and consumer satisfaction.

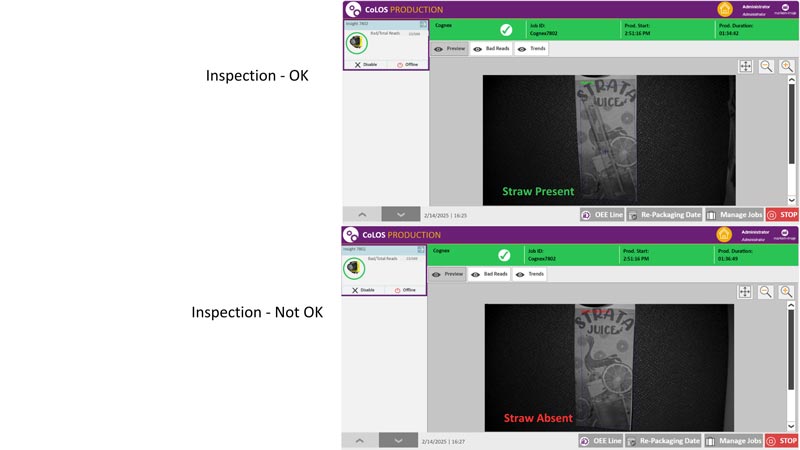

Product Inspection: Inspect for missing or damaged parts in the product

The Vision solution performs product inspection by identifying products with missing essential components, such as straws, detecting broken or compromised seals, and identifying damaged or deformed cans using AI-based technologies. This comprehensive approach ensures that products are safe, compliant, meets quality standards and consumer expectations.

Our specialized partnership with Vision Cameras and ability to seamlessly integrate IT and OT technologies allows bi-directional communication between ERP databases in real-time and trigger-based printing, unlike siloed Mark & Read systems. By implementing CoLOS® Vision Solution, beverage manufacturers get empowered to resolve complex vision projects and better collaborate with the systems to reduce packaging waste and decrease downtime. Our solution enables manufacturers to improve product quality, enhance brand reputation, and increase consumer trust. Furthermore, it facilitates compliance with regulatory requirements and industry standards, reducing the risk of errors, recalls, and reputational damage. The AI-based CoLOS® Vision Solution enables seamless coding integrity, packaging integrity, and product inspection. As the beverage industry continues to evolve, manufacturers must prioritize product quality inspection to maintain a competitive edge, ensure compliance, and protect their brand reputation.