Late-stage box printing improves your operations significantly.

Discover how!

Do you want to save packaging costs, inventory carrying costs, storage space and waste?

Do you want to increase production line efficiency, throughput and minimize operator errors?

Do you want to simplify and speed up the process of launching new product packaging?

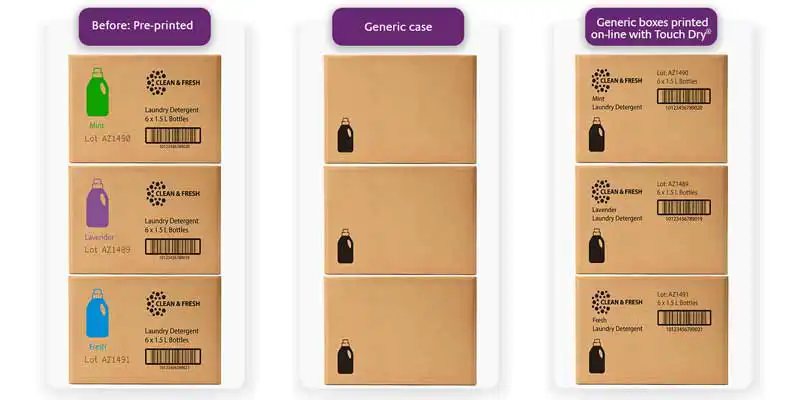

Instead of using pre-printed boxes, have you considered digitalizing the personalization of your boxes and cases and print on-line, to achieve lower costs, greater efficiency, and more sustainable operations while also protecting your brand?

At Markem-Imaje, we work with multiple leading brands globally who consistently tell us that implementing online late-stage customization of generic boxes using our dedicated solutions is the way to achieve all the above.

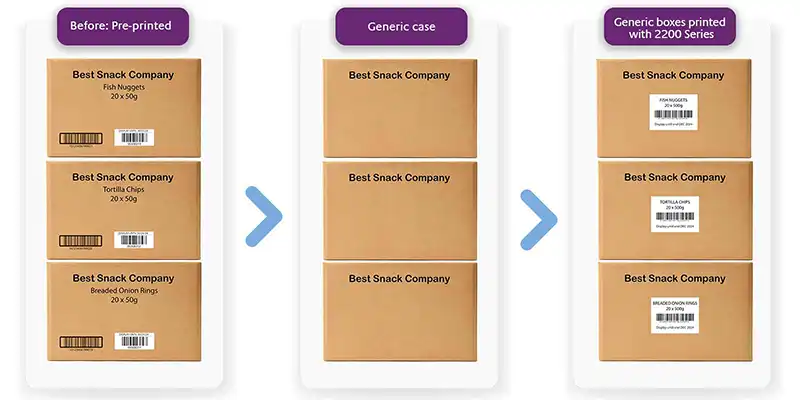

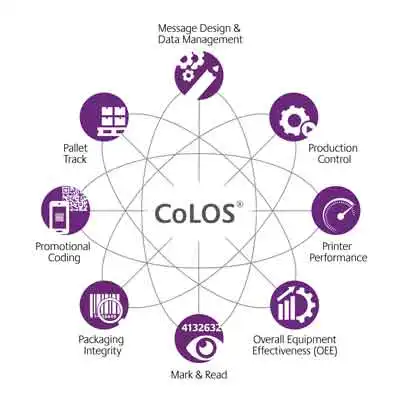

By combining Markem-Imaje’s late-stage box printing hardware, the Touch Dry® High-Resolution Inkjet printer range, or Print & Apply range of labeling machines, with our CoLOS ® Packaging Intelligence software, you can:

| |

|

| |

| |

| |

|

Customers prove generic bests pre-printed boxes using Markem-Imaje technology

Multiple Markem-Imaje customers have reduced their boxes references by up to 80% or more with positive impacts felt instantly across their packaging operations and on their pockets while avoiding the hassle of pre-printed packaging boxes. For example, a leading cereals producer reduced their SKU references from 600 to just 24 for 16 production lines using combined our Touch Dry® printers and CoLOS ® software suite. Another customer, using the same solutions, has saved over 100,000 dollars per year in printing plates and dyes since digitalizing their boxes printing when creating or modifying the artwork.

Customers using the Markem-Imaje CoLOS® software suite and 2200 Series Print & Apply labeling technology for box printing, produce labels on the spot instead of custom printed boxes achieving savings, increasing uptime as well as reducing and simplifying the launch of new products while ensuring the highest ANSI grade barcode standards.

Markem-Imaje has over 30 years of experience innovating in Touch Dry® printing technology, 2200 Series and CoLOS® Software Suite and working with FMCG customers on optimizing late-stage customization of their printed boxes, with a return of investment of typically between less than 12 and up to 18 months.

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions