Are GS1-128 Barcodes set to become the preferred standard?

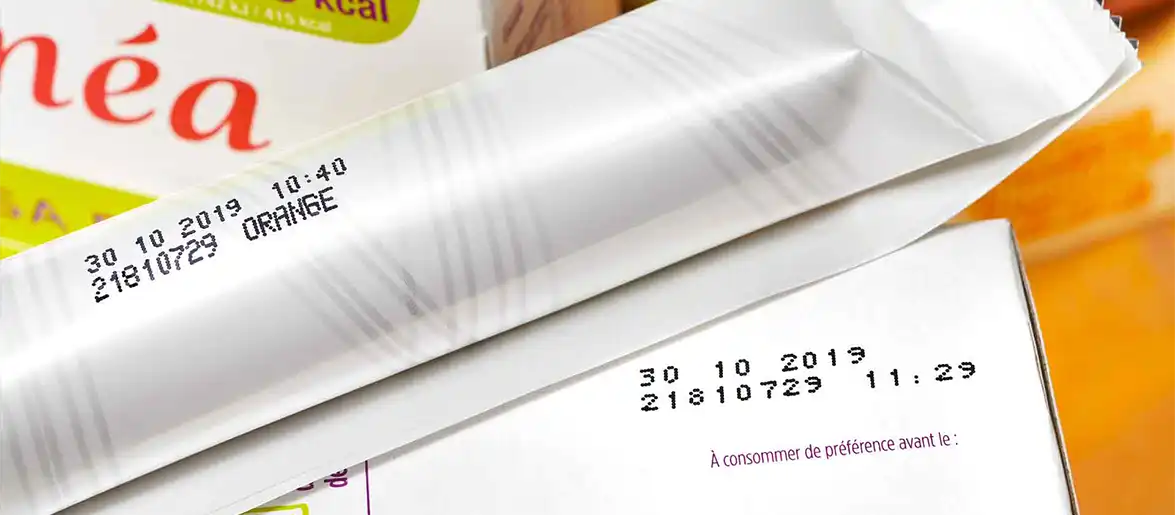

GS1-128 Barcodes: Improving Supply Chain Traceability and Efficiency.

GS1-128 Barcodes: are becoming more attractive for retailers, wholesalers, and foodservice operators keen to respond swiftly to product safety issues and improve profitability through increased pallet splitting and automation. Learn how to comply GS1-128 Barcodes and the benefits of this new technology.

“GS1-128 Barcodes have been around since 1989. Their popularity now, however, is due to increased pressure and expectations from government and consumer groups regarding traceability and speed of response when something goes wrong,” says Steven Keddie, Engineering Manager. “With the Internet, issues go viral quickly and companies need to respond faster than ever before.”

“Also, whether it be to optimize inventory levels or better match supply to demand, the technology available today means that retailers and foodservice companies are better positioned than in years gone by to extract value from the extra information available through GS1-128 Barcodes. Not embracing the GS1-128 Barcode is becoming a less and less sustainable option for manufacturers.”