IT-OT Integration

Integrate and communicate efficiently

"Everything is governed by CoLOS Software, which integrates perfectly with all the systems that manage information to be sent for printing on the product packaging."

Production Supervisor, Fiorentini

Accurate data exchange

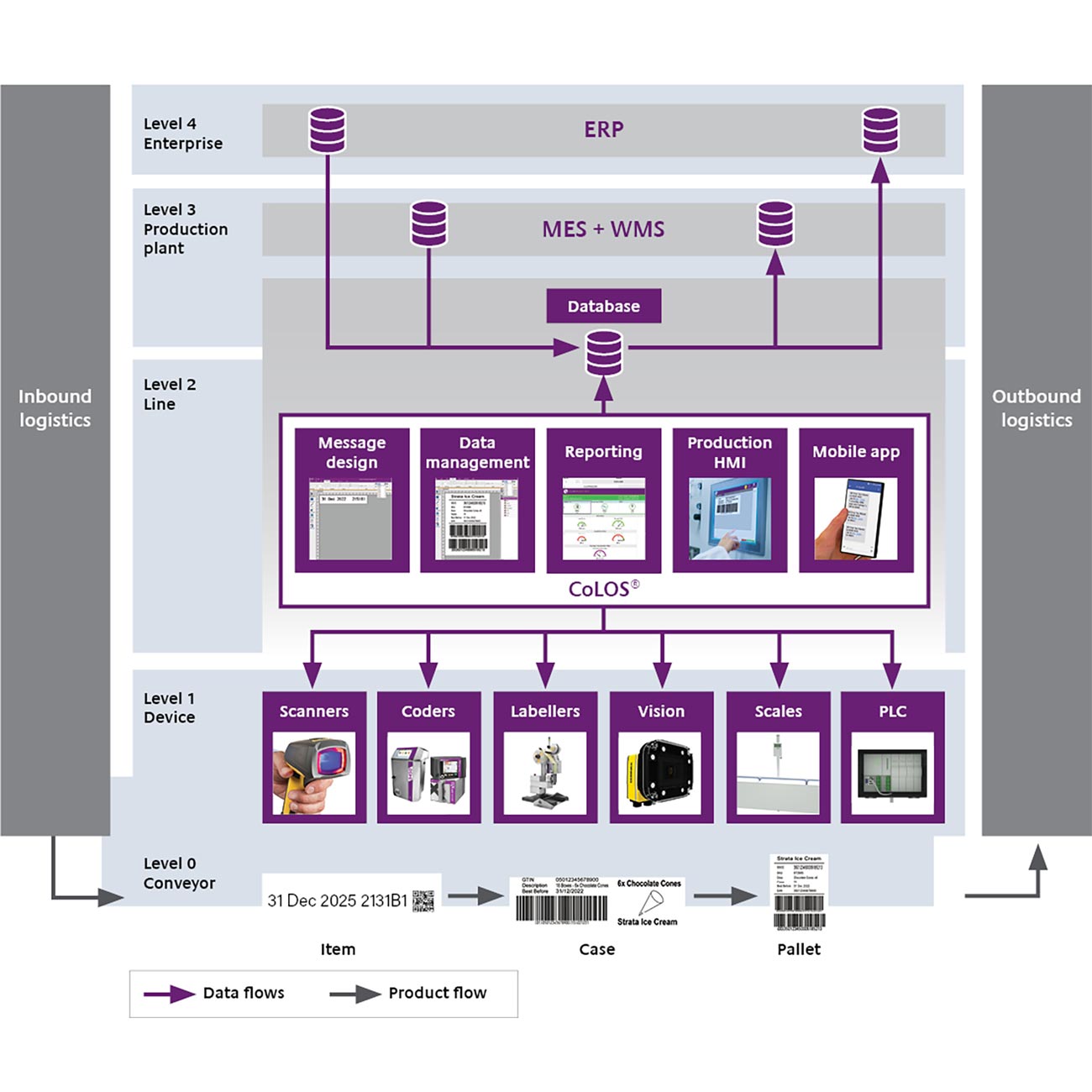

A centralized production set-up ensures that the printers and the enterprise database send and receive accurate data, thereby reducing waste and rework due to manual errors. CoLOS® IT-OT Integration supports dynamic serialization and codes for regulatory compliance and standards such as the US FDA Food Safety Modernization Act (FSMA), EU Wine Regulations, government tax systems, etc.

Inventory visibility

Enables real-time tracking and tracing of finished goods and work-in-progress products across the supply chain via ERP/Database, MES, and WMS systems. This unified view breaks down silos, providing complete visibility into inventory levels, locations, and movements, optimizing inventory management and reducing stockouts.

Real-time analytics and reporting

IT-OT integration enables real-time analytics and reporting by collecting and integrating data from IT and OT systems for real-time actionable insights, dashboards, and reports on printing quality, enabling data-driven decisions, improved efficiency, and reduced downtime.

Benefits

Synergize between business systems and operational technologies.

Enhance operational efficiencies with real-time data exchange.

Complete visibility of inventory and equipment on the packaging line.

Industries—from production to distribution

Beverage

Food

Automotive

Cosmetics

Construction

Here's what our customers are saying about our software solutions

"Everything is governed by CoLOS Software, which integrates perfectly with all the systems that manage information to be sent for printing on the product packaging."

Production Supervisor, Fiorentini

"Integration of COLOS® Software with our ERP allows us to control quality at every stage of production. Correct label on the correct pallet ensures perfect and safe traceability."

Head of Maintanance, Mezzecorona

"Thanks to the integration of CoLOS® Software with the ERP system, the data necessary to fill the correct QR are automatically uploaded, facilitating the management of data in production in real-time."

Production Manager at BISOL1542

"From packing to dispatching, everything is managed by Markem-Imaje's CoLOS® Software. It is connected to our ERP system. This solution has improved our logistics and productivity. We comply with the regulations, and our customers are more satisfied."

Plant Engineer, Evonik