How to optimize beverage coding at all packaging levels?

Beverage sector: optimizing coding at all packaging levels

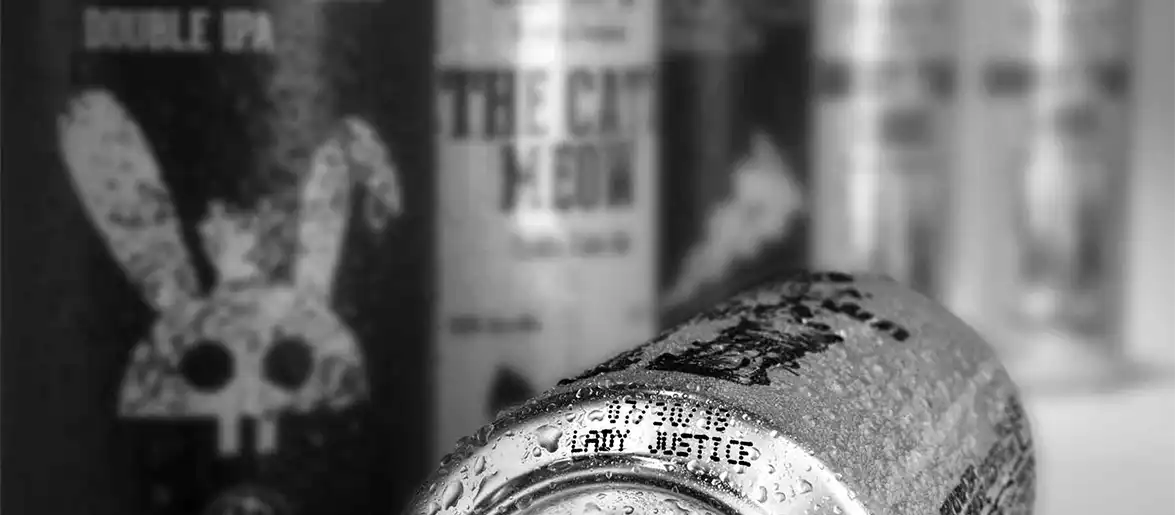

The beverage industry is growing worldwide with opportunities driven by new drink formats and changing consumer preferences. The sector has a variety of containers to code across many material types, often at high speeds. An ever-tightening regulatory and compliance framework demands traceability and fiscal marking.

Manufacturers are keen to maximize productivity and profitability through a reduction in rework and better use of resources, including greater line integration and even fully automated ‘dark factories’.

Picking the right technology for each application is therefore vital to minimize production and marketplace headaches.

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions