End-to-End Supply Chain Solutions

Markem-Imaje provides producers and machine manufacturers worldwide with a one-stop shop of innovative smart product identification, packaging intelligence, and connected product solutions to unlock the power of intelligence in codes.

Combined with our services and expertise, we enable leading brands to efficiently optimize production, and achieve sustainability goals and regulatory compliance objectives across today’s digitalized supply chain. By seamlessly integrating the most comprehensive range of proprietary coding technologies with software, services, and certified consumables, we empower our customers with the right information across the supply chain—keeping products and consumers safe and connected - this is intelligence, beyond the mark.

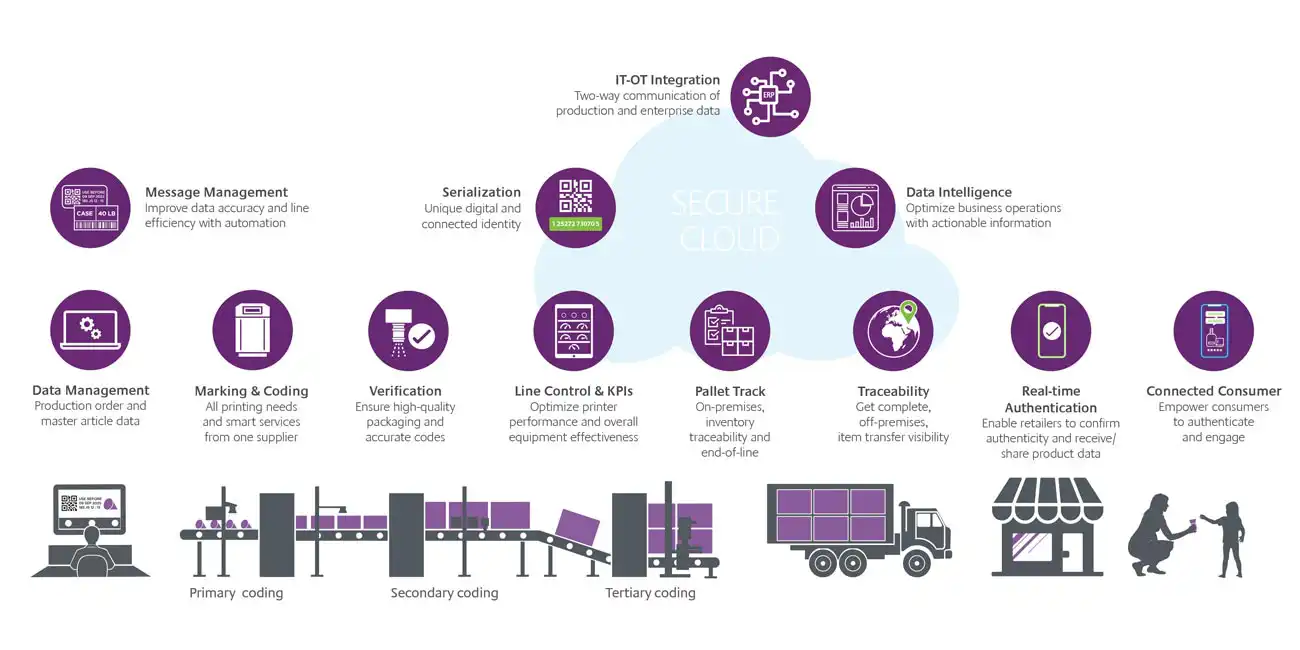

Markem-Imaje's ecosystem of solutions

Packaging intelligence and industrial coding solutions

Optimize your packaging operations with automated printing and industrial coding solutions to minimize waste, drive efficiency, and achieve compliance in any market.

We understand the operational complexity of running multiple packaging lines in the most efficient way without downtime. Our Packaging Intelligence suite maximizes uptime while ensuring your packaging and industrial coding are accurate and traceable.

Our industrial coding solutions help you reduce errors and optimize operations whether you want to improve a single line or factories worldwide. Continually improve your line efficiency and profitability with our automated solutions for message design, data management, packaging, coding verification, and line control.

- Manage complex messages and package layouts

- Eliminate incorrectly coded and packaged products

- Maximize uptime and overall equipment effectiveness (OEE)

The Packaging Intelligence solutions powered by CoLOS® are fully compatible with all Markem-Image printer technologies for seamless implementation and operation.

Brand protection and anti-counterfeiting solutions

End-to-end brand protection begins on the packaging line with the right code on the right product to deliver real-time supply chain insight, actionable data, and digital connectivity.

The ability to utilize packaging as an essential component of an anti-counterfeiting and diversion detection program is crucial to brand security. Our brand protection solutions harness cutting-edge technology and deep supply chain insight to keep products authentic, safe, and connected—from the factory to your customer’s hands.

Systech, a solutions division of Markem-Imaje, has led the industry in anti-counterfeiting technology since it first pioneered regulatory-based serialization. We’ve built on decades of expertise to develop a fully integrated brand protection platform to help you authenticate and track every product, achieve regulatory compliance, and protect your brand.

Connecting brands and consumers through products

A connected product opens the door to a set of opportunities for enhanced engagement and experience. Through printing and connecting a 2D barcode on the packaging you can offer the consumer a personalized experience and story to build loyalty and encourage reorders or related purchases.

A connected QR code enables a brand-owned communication channel that gives the consumers content that goes far beyond the limited real estate of physical packaging but also consumer-product interaction visibility with real-time product insights.

Blue Bite, a solutions division of Markem-Imaje, has since 2007 improved lives by connecting people and information through the physical world, with a solution for brands looking to surprise and delight their consumers and drive more impactful results. Blue Bite helps leading brands across the world grow brand value, drive revenue, and unlock actionable insights by transforming physical products into digital experiences.