SSCC compliant pallet labelling and CoLOS® Pallet Track solution

![]()

Tracking Compliance

Ensure proper product distribution with accurately designed, compliant labels (LPN or GS1 SSCC)

![]()

End-to-End Traceability

Ability to track each pallet at any point from production line to consumer

At Markem-Imaje, we have 30 years of experience working with major brands and manufacturers to improve their end-of-line Serial Shipping Container Code (SSCC) pallet label operations, creating the CoLOS® Pallet Track software. The software integrates your pallet operations fully with your production lines and all major Enterprise resource planning (ERP) and Manufacturing Execution Systems (MES), plus label printing technology; in total, more than 20,000 installed systems!

Our customers who have implemented CoLOS® Pallet Track to automate their end-of-line operations report:

- Maximized product output through continual operation.

- Eliminated errors caused by manual application of labels with automated code verification to guarantee compliance, reducing the risk of recalls and waste.

- More economical, safer and more streamlined warehouse operations through increased automation,

- Optimized, accurate inventory reducing costs through software integration with ERPs.

Pallet Track module offers:

- A complete software and hardware solution for all your end-of-line pallet label and management needs.

- Enhance your inventory data management in real-time.

- Fully integrated with our range of printing solutions.

- Drive standards globally across your enterprise.

- SSCC GS1-compliant labels.

Some of our Pallet Track features

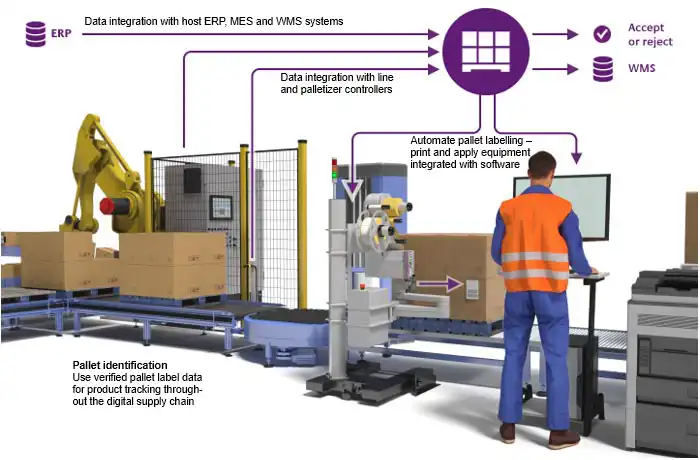

Data integration with host Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES) and Warehouse Management Systems (WMS).

Control integration with line and palletizer controllers.

GS1-compliant label design and printing.

Customizable data management, business rules and control sequences — supporting multiple languages.

Centralized software controlled SSCC generation and management.

A global offering serving different needs

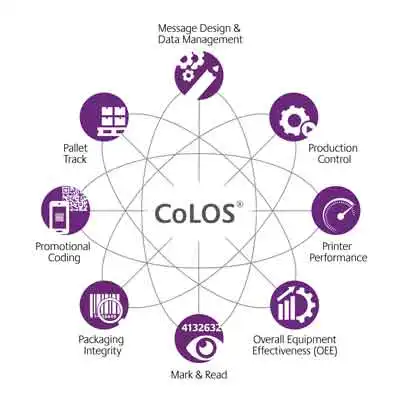

CoLOS software solutions

CoLOS Pallet Track

Automate pallet labeling, and aggregate every packaging level for seamless traceability

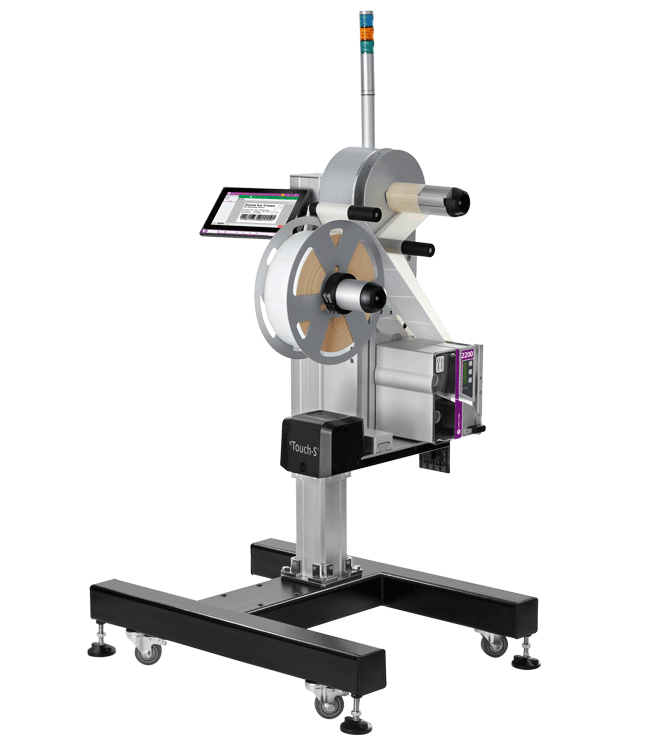

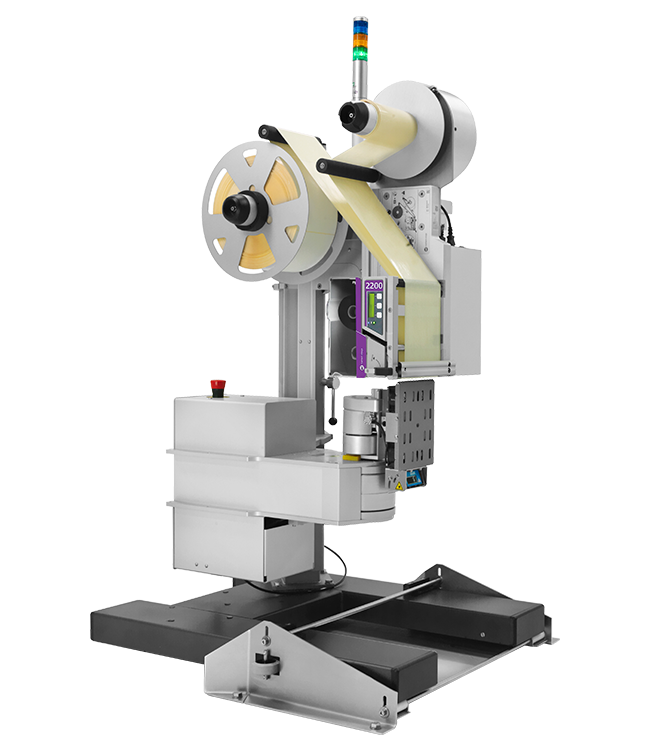

Learn moreAutomatic Print & Apply systems

2200 Series | Wipe 700

Labels on the front and side (up to 2 labels) of a pallet that is in motion

Learn more

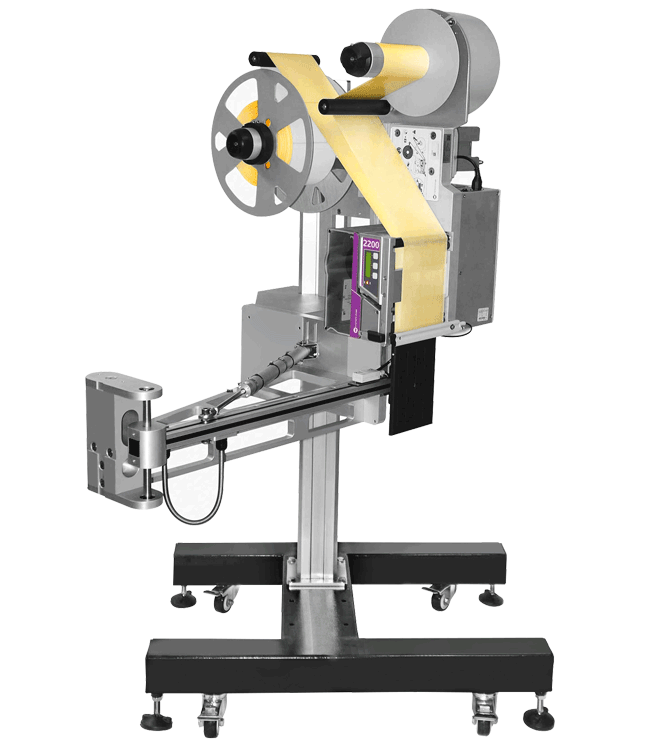

2200 Pallet

Labels on front and side, or side and rear (up to 2 labels) with verification & reapply of a stopped pallet

Learn more

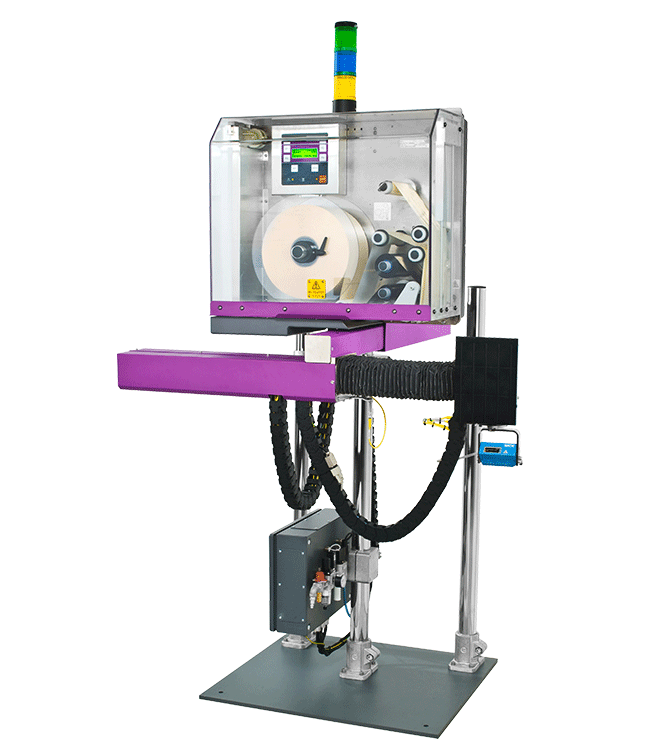

CimPak

Labels on front, side and rear (up to 4 labels) with verification and reapply of a stopped pallet

Learn more

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions