Industrial parts: rubber, plastic, and metal marking

Ensure traceability and regulatory compliance for rubber, plastic, and metal marking for industrial parts.

YOUR CHALLENGES

Metal marking and coding on plastic and rubber industrial parts, including those used in aerospace and automotive marking, must be infallible for several reasons. High-quality and durable coding are essential for brand and part identification, traceability, anti-counterfeiting measures, and regulatory compliance.

The substrates themselves are challenging for marking, especially steel, an exceptionally resistant and rigid metal, and rubber, because of its elasticity and its difficult code adherence. Additionally, some applications require industrial parts to remain static while the printhead moves, and others need the parts to be in motion while the printhead remains fixed.

When it comes to industrial plastic parts, the choice of substrate significantly affects the quality of coding. The most common industrial plastics are Polytetrafluoroethylene (PTFE), Polyethylene terephthalate (PET), Polyphenylene Sulfide (PPS), Polybenzimidazole (PBI), and Polyether ether ketone (PEEK). With many varieties of plastics available, each one has a different chemical composition affecting durability, thickness, and indelibility.

In the case of coding on rubber, the application requires either printers that can function in the most demanding of production environments and are capable of using high opacity inks, or laser coders that provide high contrast marking or deep etching on rubber.

OUR SOLUTIONS

Markem-Imaje provides proprietary innovations for all your rubber, industrial plastic, and metal marking requirements, including automotive marking, laser and CIJ offers compliant and durable solutions. These are used for metal marking in the aerospace and automotive industries because they ensure the highest levels of code quality and resistance. Thermal inkjet (TIJ), and Valvejet printer technologies, using dedicated inks, can be other suitable technologies.

Simply leave your e-mail address in the form to be contacted by one of our experts who can provide detailed information and help you find the best solution for your metal marking application or for coding on plastic industrial parts or rubber.

What our customers say about our solutions for industrial parts

"It was a tall order but thankfully the Markem-Imaje team was up to the challenge."

Russ Brown

Operations Director at Peak Pipe Systems

Quick links — Jump to the right section directly!

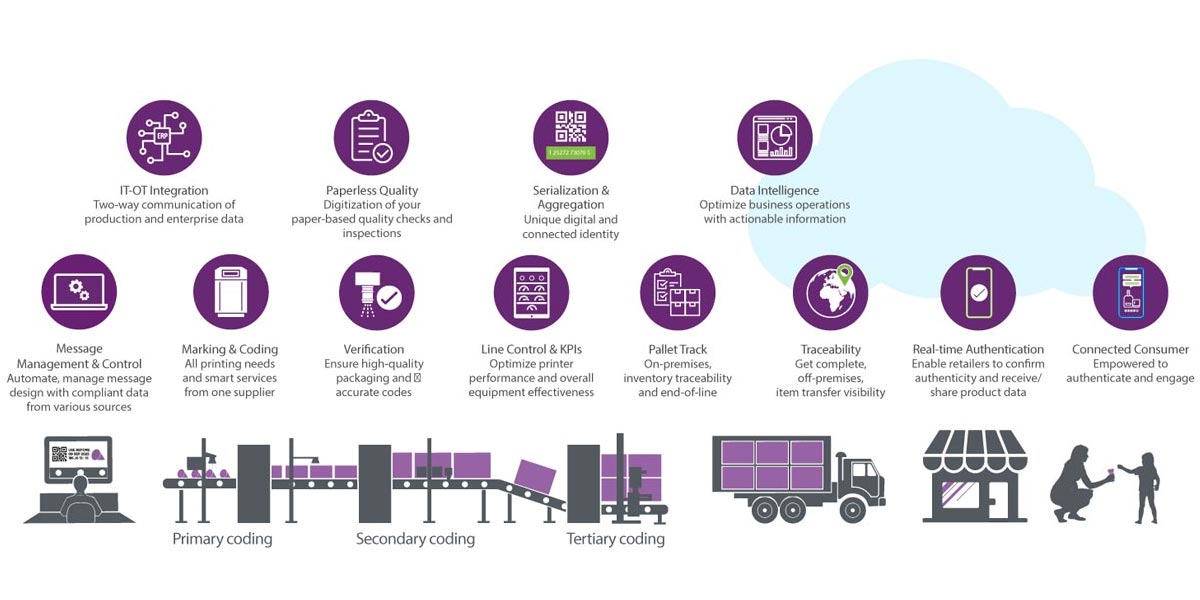

Connected Packaging and Packaging Intelligence software

Our Packaging Intelligence solutions combine our proven coding and marking expertise with our experience to deliver complete turnkey solutions for achieving the maximum packaging line efficiency, trouble-free data management, and supply chain traceability all the way to the consumer’s hands. CoLOS® will significantly enhance your productivity and quality control while also addressing the challenges of waste and costs in an ever-changing manufacturing environment, creating a smarter business. Looking for a partner to develop your product’s digital roadmap? Markem-Imaje end-to-end solutions include leading solutions for supply chain traceability and authentication through our Systech brand and an ultimate consumer engagement experience with Blue Bite.

With more than four decades of experience in continuous inkjet (CIJ) innovation, Markem-Imaje has a full range of coders for all metal marking and printing on rubber and plastic industrial parts requirements. Our vast ink portfolio, including high-performance and competitively priced MEK-free inks, makes Markem-Imaje CIJ printers the most flexible and one of the most reliable on the market today. Designed for maximum uptime and ease of use, our CIJ range simplifies daily activities and makes your printing process seamless.

Markem-Imaje 9330

CIJ printer designed for light to medium-duty production lines. The cost-efficient 9330 will cover all your basic industrial parts marking needs with up to five-line codes.

Markem-Imaje 9750

CIJ printer designed for medium-duty production lines. Our next-generation 9750 range delivers clear, customizable, traceable black or colored codes, including 2D codes (QR and DotCodes).

Markem-Imaje 9750+

CIJ printer designed for high volume lines to give you the highest flexibility, inventory, and installed-base management through a revolutionary hybrid ink circuit that is capable of managing all CIJ inks.

Markem-Imaje 9750 E

CIJ printer designed for heavy-duty production lines and the most challenging environments, the 9750 E provides high-speed and high-contrast codes with no migration, guaranteeing resistance on a wide range of industrial substrates.

View Markem-Imaje 9750 EMarkem-Imaje 9750 E+

CIJ printer designed for the highest production needs and the most complex coding applications. The 9750 E+ provides additional flexibility and convenience via a revolutionary ink circuit. It provides both standard codes or pigmented contrast printing.

View Markem-Imaje 9750 E+Markem-Imaje 9750 Ew+

CIJ printer designed for heavy-duty applications, this coder’s enhanced jet speed control brings consistent high-quality code legibility even at high speeds. The 9570 Ew+ features a dedicated printhead designed specifically to address the stretching of printed messages.

View Markem-Imaje 9750 Ew+

CIJ inks

Markem-Imaje has a complete MEK-free inks portfolio designed for metal marking or coding on plastics or rubber and is one of the few manufacturers to lower volatile organic compound emissions (VOCs) for MEK-free inks.

- Our consumables cut use and VOCs by up to 40-60%, and by up to 35% for inks with MEKs in consumable-saving mode.

- Black, white, orange, blue, green, red, yellow, and silver inks that ensure code contrast, adhesion, and resistance, regardless of substrate type (LSZH, PP, PE, PVC).

- The 9750 E Series specialty non-migrating inks meet the most challenging applications and storage conditions including resistance to high levels of heat, UV-light, automobile fluids, underwater conditions, and vulcanization.

Our SmartLase ® Fiber and UV laser printers provide high-quality, permanent codes for metal, plastic industrial parts and rubber marking, even in high-speed applications. With patented Intelli’Arc® scribing, paired with onboard Intelli’Cool®, our lasers deliver crisp, high-contrast codes with greater uptime and reliability than others.

SmartLase ® C350

Laser printer for medium to high-speed lines. The SmartLase ® C350 CO2 laser sets the standard for best-in-class laser printers for rubber. Designed to deliver permanent, crisp, clear and traceable codes, the coder is ideal for both intermittent or continuous lines.

View SmartLase® C350SmartLase ® C600

Laser printer for high-speed and demanding rubber coding needs, the SmartLase ® C600 delivers superb code quality and more power, all in an easy-to-integrate and easy-to-operate industrial grade unit, optimized for a variety of interfaces.

View SmartLase® C600SmartLase ® F250

Laser printer for high speed, crisp, permanent coding on a variety of challenging substrates and diameters. With its high uptime and OEE, SmartLase ® F250 20-watt fiber laser lowers your operating expenses and the environmental impact of your marking.

View SmartLase® F250SmartLase ® UV500

Laser printer for high-speed and the highest-quality coding with minimal heat transfer, the SmartLase ® UV500 5-watt UV laser is perfect for marking the most challenging materials.

The Markem-Imaje range of thermal inkjet printer series or TIJ printers offer high-quality compliant barcodes by heating ink that is highly accurately transferred even onto moving 2D or 3D surfaces, contact-free. They require little maintenance and excel on intermittent or low to mid-volume production lines. (Metal and plastic industrial parts offer only)

Markem-Imaje 1050

Our 1050 thermal inkjet (TIJ) printer offers precision print control at exceptional value-for-money producing codes from 12.7 mm to 50.8 mm high and can print readable 1D and 2D barcodes.

Markem-Imaje 1200

The Markem-Imaje 1200 thermal inkjet (TIJ) printer allows you to meet GS1-compliant requirements in both 1D and 2D barcodes and offers print heights from 50.8 mm to 203 mm.

The Markem-Imaje valvejet large character printers use drop-on-demand inkjet technology known as piezo and are ideal for compact or hard-to-access spaces and low-resolution marking.

Markem-Imaje 4700

Our robust 4700 large character valvejet coder offers one or two-sided printing at unmatched value with its numerous low-resolution text and logo options.

2D codes have already become an indispensable method of connecting your products to the Internet, facilitating vast amounts of product data and customization possibilities. They are also simultaneously becoming essential to comply with new regulations and standards, especially concerning traceability, including for the GS1 Digital Link, Digital Product Passport, and the US FDA’s FSMA regulations. The advantages of 2D codes for boosting brand loyalty through the supply chain are unrivaled. The possibilities for promoting sustainability efforts, packaging design efficiencies, and retail process optimization are enviable.

With the GS1 set to begin phasing out 1D barcodes in favor of 2D codes like the QR and DataMatrix from 2027, at Markem-Imaje, we have GS1 Digital Link-compliant 2D codes at the heart of our innovations from our coding hardware to software solutions supporting leading brands and retailers around the world to define and implement their connected product roadmap. Connect with us to talk to an expert or read more on our 2D solutions dedicated page!

Fill-in the form below to be contacted by one of our experts and help you find the best solution for your industrial parts.

By completing this questionnaire, you agree to the processing of your personal data by Markem-Imaje. You can consult our data protection policy at https://www.markem-imaje.com/privacy.

You may also be interested in discovering more about...

For secondary packaging coding, see our dedicated boxes and shrink-wrap offers

Find all our paperboard and box printing offers for secondary and tertiary packaging:

Corrugated case marking offers.

Find the best marking offers for products and pallets wrapped in shrink films:

Coding on shrink wraps.

Consumables and supplies

Find our genuine CIJ, DOD, TIJ, and Touch Dry Hot melt inks adapted to each marking need:

Inks and additives.

Find the thermal printing ribbon products:

Ribbons and labels.

Software

Find options to digitalize your packaging operations easily:

CoLOS software solutions.

Solutions

Find secondary packaging coding options for boxed extruded material, cables, and wires:

Late-stage box printing.

Find out how our software Solution CoLOS can help you design text, logo, line, and barcode messages for all printer types, link these to ERP master product tables and to stock-keeping units, and automatically populate messages with SKU data:

Production preparation and start-ups.

Find out how CoLOS helps you confirm that every print is present, readable and contains the right data, using a fully integrated Cognex camera:

Code and packaging verification.

Find our Packaging Intelligence Solution to enhance and achieve traceability:

CoLOS traceability solutions.

Find out how to authenticate each individual product is the most effective way to protect your brand by preventing its counterfeiting or diversion:

Authentication.

Find out how to ensure your coding is correct, compliant, and cost-effective:

Serialization solutions.

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions