Printing on plastic offers

Durable, 100% readable codes even on challenging rigid plastic substrates.

YOUR CHALLENGES

Rigid plastics encompass a wide variety of compositions and shapes used in many FMCG applications from bottle caps to cosmetics, and across wider industry as both components and containers, for their environmental and chemical resilience, for example in automobiles and electronics. Their sheer variety presents challenges when it comes to selecting the correct marking technology for your printing on plastic application. Each rigid plastic has a different chemical composition affecting durability, thickness, and indelibility.

Additionally, there are ever more demands across market segments, including:

- A requirement for durable and resilient coding technology to withstand the harsh environmental conditions or chemical contents rigid plastics are often made for.

- An increasing need to include more information on the substrate e.g. for traceability, and to code in more complex formats, including in 2D, like QR codes.

- Requirement to code at higher production speeds, especially in FMCG applications, with a need to maintain consistently excellent quality.

- The use of ever more recyclable plastic composites with different coding requirements due to demands for waste reduction and increased sustainability.

Fortunately, we can help you find your ideal printing on plastic solutions.

Please note:

This page has solutions for printing on plastic caps and other rigid plastics, mainly for FMCG applications.

However, if you are looking for printing on plastic bottle solutions, please see our plastic bottle printing dedicated page.

If you are looking for printing on plastic industrial parts, please see our industrial plastic and metal parts marking dedicated page.

OUR SOLUTIONS

There are numerous reasons why rigid plastics are used across FMCG and multiple industrial sectors besides their durability. These plastics are highly versatile and easily moldable into multiple forms suitable for varied industries, making them highly customizable and ideal for coding branding designs. They are relatively cheap to produce yet look more expensive due to their sturdiness and ability to be turned into elaborate shapes with decorative elements for multiple segments. They are also relatively lightweight and increasingly recyclable, with some of the most commonly used today, all catered for by Markem-Imaje coding technology, including:

- PET or PETE (Polyethylene terephthalate)

- PE - HDPE (High-density Polyethylene), recyclable when not bonded with other composites

- PP (Polypropylene), increasingly recycled

- PS (Polystyrene), increasingly recycled

- PVC (Polyvinyl Chloride), increasingly recycled

- PA (polyamide), increasingly recycled

- PC (Polycarbonate), increasingly recycled

- ABS (Acrylonitrile butadiene styrene copolymer), increasingly recycled

There are also numerous composites using the above polymers which are suitable for coding with Markem-Imaje printing on plastic solutions. For example, plastic bottle caps which are usually made with HDPE and PP, are now attached to the plastic, usually PET, bottle itself, and can today be recycled together in many markets.

Markem-Imaje provides innovative proprietary solutions for all your printing on plastic requirements, including the most rigid varieties and caps, across five technologies: Continuous inkjet (CIJ), CO2, fiber and UV laser printing, and Print & Apply (P&A) labeling.

Our role goes beyond providing innovative coding technologies; it extends to providing invaluable software and services, supporting regulatory compliance, conducting sample process reviews, and offering advice on the role of marking and coding in Environmental, Social, and Governance (ESG) strategies.

Simply leave your e-mail address in the form to be contacted by one of our experts who can provide detailed information and help you find the best solution for your printing on plastic requirements.

What our customers say about our solutions

The topic of packaging is a perennial issue for us. There is a growing demand for better recyclability of packaging. We need strong partners who will work with us to drive innovation, to support us on how we can save more packaging material and use environmentally friendly materials.

Christine Breyer, Marketing Manager at Töpfer

Quick links — Jump to the right section directly!

Connected Packaging and Packaging Intelligence software

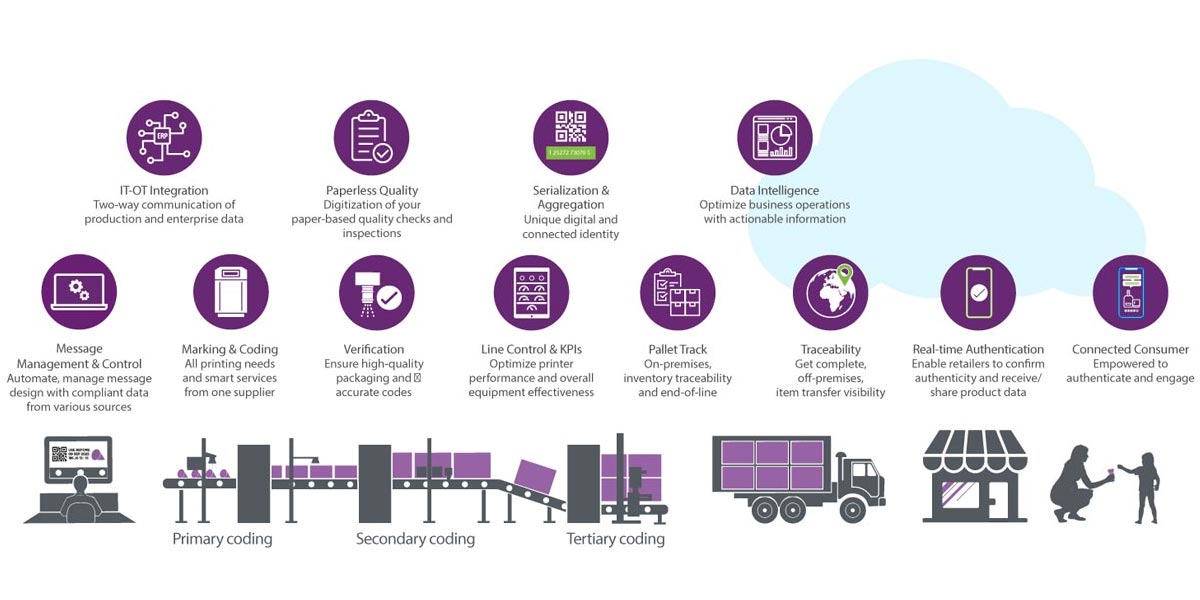

Our Packaging Intelligence solutions combine our proven coding and marking expertise with our experience to deliver complete turnkey solutions for achieving the maximum packaging line efficiency, trouble-free data management, and supply chain traceability all the way to the consumer’s hands. CoLOS® will significantly enhance your productivity and quality control while also addressing the challenges of waste and costs in an ever-changing manufacturing environment, creating a smarter business. Looking for a partner to develop your product’s digital roadmap? Markem-Imaje end-to-end solutions include leading solutions for supply chain traceability and authentication through our Systech brand and an ultimate consumer engagement experience with Blue Bite.

With more than four decades of experience in Continuous Inkjet (CIJ) innovation, Markem-Imaje has a full range of coders for printing on plastic, including the most rigid types. Our vast ink portfolio, including competitively priced MEK-free inks and reduced VOC varieties for reduced environmental impact, makes Markem-Imaje CIJ printers the most flexible and one of the most reliable on the market today. Designed for maximum uptime, TCO and ease-of-use, our CIJ range simplifies daily activities and makes your coding process seamless.

Markem-Imaje 9330

CIJ printer designed for light to medium duty production lines, the 9330 series offers versatility, cost-effectiveness and longevity, covering all your basic printing on plastic needs, including for rigid plastics, with the capacity to code

for more than 8,000 hours non-stop.

Markem-Imaje 9750

CIJ printer designed for medium to heavy-duty production lines, the 9750 is primed for digitalization and traceability with its unique 24-pin interface delivering clear, customizable, traceable black or colored codes, including 2D codes (QR and DotCodes), in a modular format which is easy-to-use.

Markem-Imaje 9750+

CIJ printer designed for heavy-duty production lines and the most challenging environments, the 9750+ provides high-speed and high-contrast codes with no migration, guaranteeing resistance on a wide range of industrial substrates, including the most rigid plastics.

Markem-Imaje 9750 Expert Series

CIJ printer designed for the most challenging FMCG coding operations, the market-first 9750 Expert Series of CIJ printers has been innovated to mark tiny surfaces, deliver enhanced 2D messages, including QR codes, and only requires one type of coder for dye or pigment prints.

View Markem-Imaje 9750 Ew+

CIJ Consumables for printing on plastic

We offer a full range of proprietary inks to match your requirements to print on plastic. Our consumables range includes permanent, non-transferable, high-adhesion inks, with a full range of colors and MEK-free varieties, ideal for FMCG printing as well as other segments across multiple industries.

Our SmartLase ® CO2, fiber, and UV laser printers provide high-quality, permanent codes for all laser printing on plastic needs, including for the most rigid varieties. With patented Intelli’Arc® scribing, paired with onboard Intelli’Cool® to lower temperatures, our lasers deliver crisp, high-contrast codes with greater uptime and reliability than others. Our lasers also meet the highest standard of safety for E-stop and interlock circuits, ISO 13849-1 / PLe 4.

SmartLase ® C150 and C350

Laser printer designed for medium to high-speed intermittent or continuous lines, the SmartLase ® C150 and C350 30-watt CO2 lasers deliver permanent, crisp, clear, and traceable codes, perfect to print on plastic of all compositions, 30% faster than other lasers, at up to 150,000 products per hour.

View SmartLase® C150 and C350SmartLase® C340

Laser printer designed to be a complete and cost-effective 30-watt CO2 laser that is suitable for basic printing on plastic, coding up to 125 meters per minute. The C340 is subject to regional availability.

SmartLase® C350 BOU

Designed for tight spaces where other laser coders cannot reach, the SmartLase ® C350 BOU (Beam Orientation Unit) offers easy integration in medium to high-speed production lines with the highest quality indelible codes for printing on

plastic of all types, including 1D and 2D codes.

SmartLase ® C600

Laser printer designed for high-speed applications like beverage coding and for the most challenging Industry 4.0 environments. Our most advanced CO2 laser coder, the SmartLase ® C600 delivers superb code quality and more power, even with 1D and large 2D codes, at rates of up to 150,000 products per hour, according to the application.

View SmartLase® C600SmartLase ® F250

Laser printer for high speed, crisp, permanent coding on a variety of challenging rigid plastic materials and diameters. With its high uptime and OEE, the SmartLase ® F250 20-watt fiber laser lowers your operating expenses and the environmental impact of your laser printing on plastic operations.

View SmartLase® F250SmartLase® UV 500

Laser printer designed for high-speed on high-density materials including flexible films, our SmartLase® UV500 5-watt UV laser delivers the most precise, high-quality coding with the added benefit of minimal heat transfer.

With decades of experience in Print and Apply (P&A) labeling technology, Markem-Imaje labelers provide the highest print quality with Grade ‘A’ GS1 compliant barcodes, including the Digital Link, while being reliable, efficient, and easy to use.

Markem-Imaje 2200 Series

Able to print and apply at over 150 packs per minute, regardless of code complexity, we offer a wide range of interchangeable applicators for each of your rigid plastics applications, minimizing line changes, including AI-enhanced and automation-enabling options.

View Markem-Imaje 2200 SeriesMarkem-Imaje has decades of experience with our easy-to-integrate, operate, and maintain high-resolution piezo Large Character Inkjet (LCIJ) printers and our non-hazardous, solvent-free Touch Dry® hot melt ink that solidifies on contact and produces darker, high-quality codes. Our LCIJ printers with Touch Dry ink are the ideal solutions for marking and coding, including GS1 compliant 1D and 2D barcodes and logos, all with lower TCO.

Markem-Imaje 5800

Offering a lower-cost solution and employing the same instantly solid Touch Dry® ink technology for medium throughput applications, the 5800 is equipped with unique printheads that use smaller ink blocks inserted directly into the printhead and allow for the use of up to 4 different colors of ink on the same line.

View Markem-Imaje 5800Markem-Imaje 5940 G

Using Touch Dry® ink technology for consistently scannable 1D and 2D compliant barcodes with maximized uptime and great throughput thanks to its larger ink supply, the 5940 G is built to be reliable even in tough industrial environments and features Intelli’Flow® technology to keep printhead jets clear.

View Markem-Imaje 5940 G2D codes have already become an indispensable method of connecting your products to the Internet, facilitating vast amounts of product data and customization possibilities. They are also simultaneously becoming essential to comply with new regulations and standards, especially concerning traceability, including for the GS1 Digital Link, Digital Product Passport, and the US FDA’s FSMA regulations. The advantages of 2D codes for boosting brand loyalty through the supply chain are unrivaled. The possibilities for promoting sustainability efforts, packaging design efficiencies, and retail process optimization are enviable.

With the GS1 set to begin phasing out 1D barcodes in favor of 2D codes like the QR and DataMatrix from 2027, at Markem-Imaje, we have GS1 Digital Link-compliant 2D codes at the heart of our innovations from our coding hardware to software solutions supporting leading brands and retailers around the world to define and implement their connected product roadmap. Connect with us to talk to an expert or read more on our 2D solutions dedicated page!

Leave your e-mail address in the form to be contacted by one of our experts who can provide detailed information and can help you find the best solution for your printing on plastic needs.

You may also be interested in discovering more about...

Consumables and supplies

Inks and additives: find our genuine CIJ, DOD, TIJ, and Touch Dry Hot melt inks adapted to each marking need.

Ribbons and labels: find the thermal printing ribbon products.

Software

CoLOS® industrial software solutions: find options to digitalize your packaging operations easily.

Solutions

Find out how CoLOS can increase your pallet labeling process: SSCC Pallet Labeling

Find out our Packaging Verification solutions