Printing on aluminum, cans, caps and lids offers

Printing on aluminum cans, caps and lids for permanent codes to ensure safety and traceability in the food and beverage industries.

YOUR CHALLENGES

Printing on aluminum, including aluminum can printing and coding on caps and lids, is an essential application for many FMCG brands’ food and beverage operations but presents a number of challenges. Your business is under pressure to tackle the requirements of varied product substrates and shapes, tough production environments, and increasing regulatory demands.

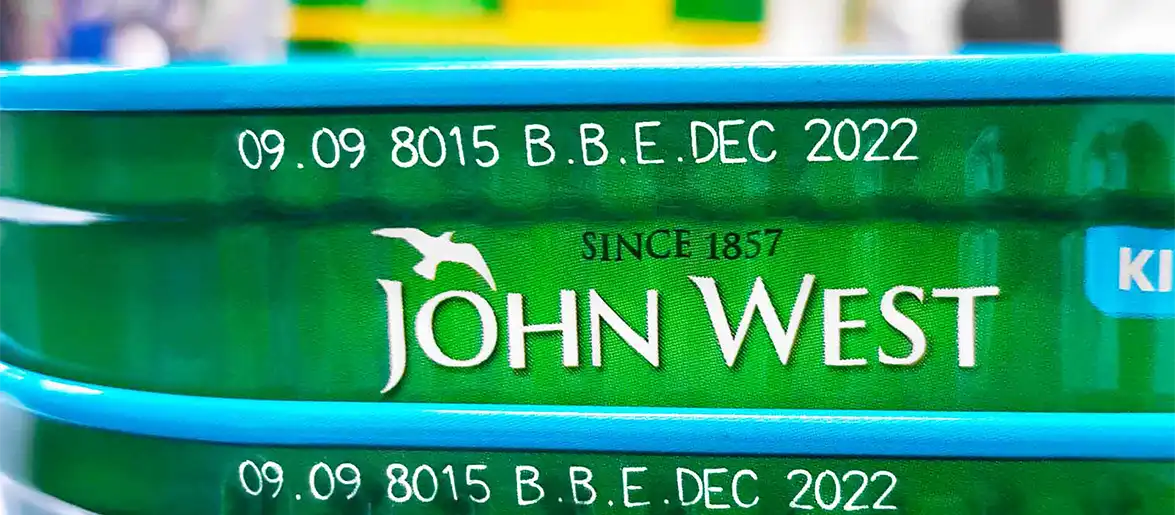

The FMCG products made of aluminum usually come in packs and comprise multiple units, meaning printing must be done over multiple print fields and a large surface area, for example, coding on yogurt lids. These are generally high-speed operations that simultaneously require high-quality coding quality to meet strict verification, regulatory and traceability standards, with a need to be highly legible and durable.

Additionally, in applications such as aluminum can printing, the moist conditions of the substrate can be a challenge for producing effective coding, resulting in spoilt codes if the right printing technology is not selected. There is also an increasing demand for tin can printing to mark on the top of cans and caps for promotional, tax, or brand reasons which can be impossible if the incorrect technology is selected. For food products like yogurts that are often marked on the production line and sealed with a metalized polyester film lid, there must be a barrier against external contaminants, and any inks used must be food grade.

OUR SOLUTIONS

The ability of aluminum to maintain food and beverage freshness and its recyclability make printing on aluminum substrates a top and enduring choice for packaging in these industries.

With unrivalled expertise in empowering food and beverage companies to achieve their goals, we provide extensive options for high-resolution, high-speed printing on aluminum cans, caps, and lids. As a global leader in industrial coding solutions for FMCG brands over decades, we enable manufacturers to optimize their coding processes, achieve compliance and protect their brands and consumers.

Resolve your product coding issues with solutions designed to maximize uptime, output, and quality while minimizing waste and hassle.

Our printing on aluminum solutions ensure that cans, caps, and lids remain fully recyclable and provide both sterility and a long shelf life for canned food, pet food, and beverages. Coding for yogurts, desserts, and other products packaged in cups with metalized polyester film lids that are usually heat-sealed is another popular application in which we have a longstanding record of innovation.

Markem-Imaje offers a wide range of printers across the technologies of continuous inkjet (CIJ) and fiber and CO2 laser primed for all your printing on aluminum can, cap, and lid applications and requirements.

Simply leave your e-mail address in the box to the right of this page to be contacted by one of our experts who can provide detailed information and can help you find the best solution for your application, whether it is a wire printer or coder for cables, pipes or different varieties of extruded products.

What our customers say about our solutions

“Markem-Imaje is the only one that fully reassured us that their laser had the capacity to keep up with our production rate, even in overspeed cases.”

Yannick Joubert

Senior Manager Plant Engineering & Technology at CCEP — French subsidiary of Coca-Cola European Partners

“It was essential that we find a supplier who could cover the vast range of packaging materials we use for our products. We needed a coding solution for PET, glass, paper, aluminum, and a secondary and tertiary packaging labeling solution for our cartons and pallets. We needed clarity, precision, perfect quality, and legible messages at a high output speed of up to 60,000 bottles/ hour. With Markem-Imaje we found the partner we were looking for.”

Raffaele Bini

Engineering Manager at Sanpellegrino

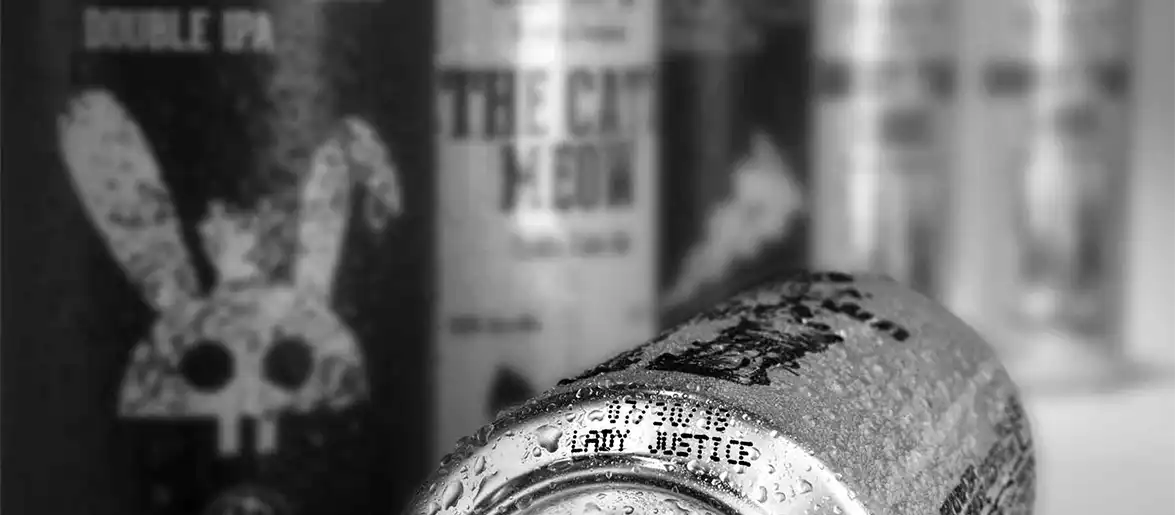

“From day one, we’ve had nothing but great experiences with Markem-Imaje. We’re pleased with the quality of the printer, and it will be able to keep up with our needs as we grow.”

Matthew Steinberg

Exhibit ‘A’ Cofounder and Head Brewer

Quick links — Jump to the right section directly!

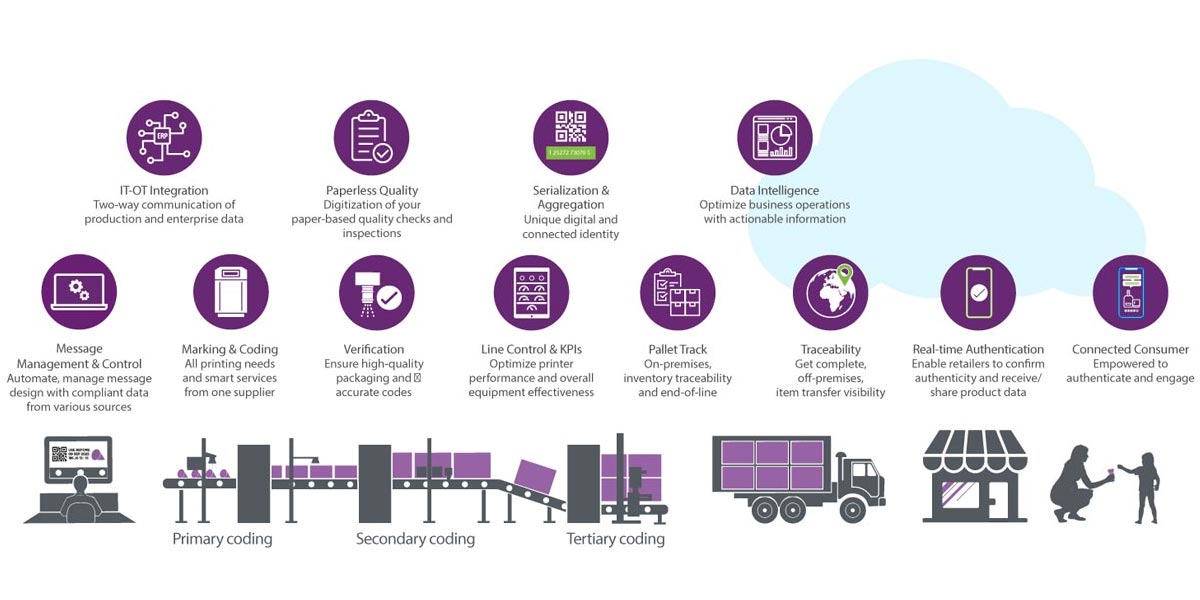

Connected Packaging and Packaging Intelligence software

Our Packaging Intelligence solutions combine our proven coding and marking expertise with our experience to deliver complete turnkey solutions for achieving the maximum packaging line efficiency, trouble-free data management, and supply chain traceability all the way to the consumer’s hands. CoLOS® will significantly enhance your productivity and quality control while also addressing the challenges of waste and costs in an ever-changing manufacturing environment, creating a smarter business. Looking for a partner to develop your product’s digital roadmap? Markem-Imaje end-to-end solutions include leading solutions for supply chain traceability and authentication through our Systech brand and an ultimate consumer engagement experience with Blue Bite.

With more than four decades of experience in Continuous Inkjet (CIJ) innovation, Markem-Imaje has a full range of coders for all printing on aluminum requirements. Our vast ink portfolio, including high-performance competitively priced MEK-free inks, makes Markem-Imaje CIJ printers the most flexible and one of the most reliable on the market today. Designed for maximum uptime and ease of use, our CIJ range is highly suited to aluminum can, cap, and lid printing in the food and beverage industries. Specialized color-changing inks serve as a visual quality control indicator that metal cans filled with food or drink have successfully completed the high-pressure sterilization process. We also offer inks visible only in UV light as an anti-counterfeiting measure.

Markem-Imaje 9330

CIJ printer designed for light to medium-duty production lines. The cost-efficient 9330 will cover all your basic extrusion product coding needs and is available with an extrusion-dedicated yellow semi-pigmented permanent and MEK-free ink.

View Markem-Imaje 9330Markem-Imaje 9750

CIJ printer designed for medium-duty production lines. Our next generation 9750 range delivers clear, customizable, traceable black or colored codes, including 2D codes (QR and DotCodes).

Markem-Imaje 9750+

CIJ printer designed for heavy-duty production lines, the revolutionary 9750+ is the first CIJ printer with a polyvalent ink circuit with the flexibility to print standard dark codes or color-contrasted codes using either dyes or pigmented inks.

View Markem-Imaje 9750+Markem-Imaje 9750 Expert Series

CIJ printer designed for the most challenging FMCG coding operations, the market-first 9750 Expert Series of CIJ printers has been innovated to mark tiny surfaces, deliver enhanced 2D messages, including QR codes, and only requires one type of coder for dye or pigment prints.

View Markem-Imaje 9750 Expert Series

CIJ inks

We offer a full range of MEK-free inks in multiple colors with both dyes and pigmented inks to match your printing on aluminum needs. Our consumables range includes water-resistant, permanent, food-grade, fast-drying, and thermochromic inks.

Our SmartLase ® Fiber, CO2, and UV laser printers, the latter available in 3- or 5-watt models, provide high-quality aluminum printing, whether it is tin can printing, or coding on metal caps or lids, including metalized film lids. With patented Intelli’Arc® scribing, paired with onboard Intelli’Cool®, our lasers deliver crisp, high-contrast codes with greater uptime and reliability than other lasers.

Benefits of Markem-Imaje laser technology:

- High uptime and OEE.

- Low TCO and reduced environmental impact.

- High coding speed.

- High-quality codes.

- Chemical-free.

- Permanent marking.

SmartLase ® F250

The SmartLase F250 20-watt fiber laser offers superb code quality at high-speed applications on bare aluminum cans, caps and lids, including metalized foil lids, even with the increasing code complexity associated with 1D and 2D codes.

View SmartLase® F250SmartLase ® C350

The SmartLase ® C350 CO2 laser offers superb code quality at high-speed applications on coated aluminum cans, caps, and lids, even with the increasing code complexity associated with 1D and 2D codes.

View SmartLase® C350SmartLase ® C350 HD and HD+

The SmartLase ® C350 HD and HD+ industrial laser printer series guarantees high contrast codes on wide print areas, multi-lane and matrix applications, perfect for coding on metalized film lids used for yogurts and desserts.

View SmartLase® C350 HD and HD+SmartLase ® C600

The SmartLase ® C600 laser printer delivers superb code quality and more power for high-speed applications, perfect for 1D and 2D code printing in challenging environments. Our most advanced CO2 laser marking coder comes optimized for multiple Industry 4.0 applications.

View SmartLase® C600SmartLase ® C600 X-WIDE

The SmartLase ® C600 laser printer is the most advanced CO2 laser marking coder in our line-up, plus its X-WIDE printhead, this laser delivers high-quality, permanent coding on matrix product packaging on a whole new scale, for a print

area of up to 820 x 500 mm.

2D codes have already become an indispensable method of connecting your products to the Internet, facilitating vast amounts of product data and customization possibilities. They are also simultaneously becoming essential to comply with new regulations and standards, especially concerning traceability, including for the GS1 Digital Link, Digital Product Passport, and the US FDA’s FSMA regulations. The advantages of 2D codes for boosting brand loyalty through the supply chain are unrivaled. The possibilities for promoting sustainability efforts, packaging design efficiencies, and retail process optimization are enviable.

With the GS1 set to begin phasing out 1D barcodes in favor of 2D codes like the QR and DataMatrix from 2027, at Markem-Imaje, we have GS1 Digital Link-compliant 2D codes at the heart of our innovations from our coding hardware to software solutions supporting leading brands and retailers around the world to define and implement their connected product roadmap. Connect with us to talk to an expert or read more on our 2D solutions dedicated page!

Fill in the form below to be contacted by one of our experts who can provide detailed information to help you find the best solution for your application for printing on aluminum, whether it is tin can printing, or coding on metal caps or lids, including metalized film lids.

By completing this questionnaire, you agree to the processing of your personal data by Markem-Imaje. You can consult our data protection policy at https://www.markem-imaje.com/privacy.

You may also be interested in discovering more about...

For secondary packaging coding, see our dedicated boxes and shrink-wrap offers

Find all our paperboard and box printing offers for secondary and tertiary packaging:

Corrugated case marking offers.

Find the best marking offers for products and pallets wrapped in shrink films:

Coding on shrink wraps.

Consumables and supplies

Find our genuine CIJ, DOD, TIJ, and Touch Dry Hot melt inks adapted to each marking need:

Inks and additives.

Find the thermal printing ribbon products:

Ribbons and labels.

Software

Find options to digitalize your packaging operations easily:

CoLOS software solutions.

Solutions

Find secondary packaging coding options for boxed extruded material, cables, and wires:

Late-stage box printing.

Find our unique in-the-market solutions that help you throughout the supply chain:

End-to-End Supply Chain Solutions.

Find out how to optimize beverage coding at all packaging levels:

Optimized beverage coding.

Find our Packaging Intelligence Solution to enhance and achieve traceability:

Traceability solutions.

Find industry hot topics that benefit from using 2D barcodes for connected products:

Connected and compliant 2D barcodes.

Find our unique back-end IoT solution that connects Industrial Software Systems, ERP, CRM, coupon, and loyalty programs:

Consumer engagement.

Find our CoLOS helps you apply unique marketing codes to each and every product at full line speeds and with the flexibility of both always-on and “on-demand” promotions:

Product Distribution and Compliance.

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions