Printing on shrink wrap film

Printing on shrink wrap film for 100% high quality, cost-effective codes ensuring end-to-end traceability of products packaged in wraps and films.

YOUR CHALLENGES

Printing on shrink wrap film for either retail or logistics operations across all packaging stages creates some critical challenges that not all coders can address. Not choosing the optimal technology, the correct ink, or adhesives when printing on shrink film can result in errors and costly downtime. Printing on shrink wrap film which includes stretch films, some flexible films, and vacuum packs, has become increasingly complex for several reasons:

- A need to include additional data for traceability and for commercial benefit, such as promotional information and QR codes.

- Demand for waste reduction and increased sustainability, meaning reducing film thickness to cut material use which can be challenging for coding.

- Increasing demand for biodegradable and recyclable film which does not necessarily have the same properties as standard film and presents challenges for code quality and/or requires lower machine speeds.

- Ever faster production speeds.

When it comes to printing on shrink wrap film, due to the huge variety in the shape, usage, and composition of today’s films and wraps in terms of materials, there is no hard and fast rule on which technology is best on the substrate. This is why Markem-Imaje, an expert in the development of shrink wrap film coding solutions, is here to assist you.

OUR SOLUTIONS

Printing on shrink film of different varieties is a more popular application in FMCG operations for coding products’ primary and secondary packaging and for printing on pallets. Whether the substrate in question is polyolefin, PVC, polyethylene, or even polypropylene, with the right approach to printing on shrink-wrap film, businesses can achieve advanced end-to-end traceability of products throughout the distribution chain, significantly reducing the risk of costly recalls. The rigorous compliance requirements that companies are required to meet can be achieved through GS1-compliant codes, including increasingly in 2D, like the GS1 Digital Link QR or Data Matrix codes.

Within printing on shrink wrap film for primary packaging on products like flexible films and vacuum packs, we offer a selection of compliant technologies including Print and Apply (P&A) labeling, thermal transfer overprinting (TTO), continuous inkjet (CIJ), fiber, CO2 and UV laser and thermal inkjet (TIJ), ensuring accuracy, safety, and superior traceability.

For your printing on shrink film for secondary packaging operations, Markem-Imaje offers a range of solutions across Print and Apply, Large Character High-Resolution Piezo (LCIJ), thermal inkjet (TIJ) and valvejet printing technologies. Please scroll down to see our secondary packaging offers for printing on shrink film.

If you need printing on pallets for tertiary packaging operations, we provide a tailor-made Print and Apply solution so please scroll down to the relevant section to see the offer.

Please note that if you are looking for non-shrink flexible films for on-product coding, please visit our dedicated flexible film webpage.

Simply leave your email address in the form to be contacted by one of our experts who can provide detailed information to help you find the best solution for your printing on shrink wrap film application, whether it is for primary, secondary or pallet packaging.

What our customers say about our solutions for printing on shrink wrap film

"The food market has become increasingly demanding in terms of traceability, food safety and waste management., We know that we can count on Markem-Imaje as a partner to help us meet these requirements."

Andrea Boccolini

Technical Sales Support Manager at Ilapack

"In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. "

Andreas Wehl

Head of Packaging Innovation and Cosmetics at Töpfer

Quick links — Jump to the right section directly!

Product coding

Case or pallet coding

Connected Packaging and Packaging Intelligence software

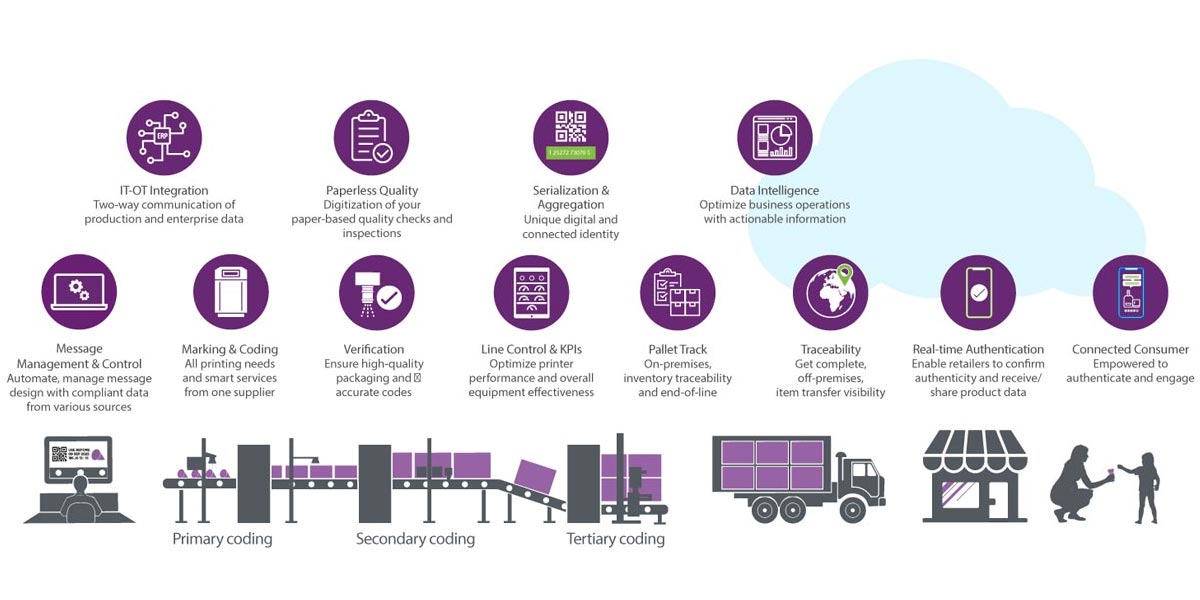

Our Packaging Intelligence solutions combine our proven coding and marking expertise with our experience to deliver complete turnkey solutions for achieving the maximum packaging line efficiency, trouble-free data management, and supply chain traceability all the way to the consumer’s hands. CoLOS® will significantly enhance your productivity and quality control while also addressing the challenges of waste and costs in an ever-changing manufacturing environment, creating a smarter business. Looking for a partner to develop your product’s digital roadmap? Markem-Imaje end-to-end solutions include leading solutions for supply chain traceability and authentication through our Systech brand and an ultimate consumer engagement experience with Blue Bite.

2D codes have already become an indispensable method of connecting your products to the Internet, facilitating vast amounts of product data and customization possibilities. They are also simultaneously becoming essential to comply with new regulations and standards, especially concerning traceability, including for the GS1 Digital Link, Digital Product Passport, and the US FDA’s FSMA regulations. The advantages of 2D codes for boosting brand loyalty through the supply chain are unrivaled. The possibilities for promoting sustainability efforts, packaging design efficiencies, and retail process optimization are enviable.

With the GS1 set to begin phasing out 1D barcodes in favor of 2D codes like the QR and DataMatrix from 2027, at Markem-Imaje, we have GS1 Digital Link-compliant 2D codes at the heart of our innovations from our coding hardware to software solutions supporting leading brands and retailers around the world to define and implement their connected product roadmap. Connect with us to talk to an expert or read more on our 2D solutions dedicated page!

Shrink wraps for primary packaging offers

Markem-Imaje excels in the production of the highest quality yet cost-effective compliant innovations for printing on shrink wrap film in primary packaging applications including flexible films and vacuum packs. We offer a full range of different technologies for printing on shrink film to fulfill every requirement working with these variable substrates, with each solution able to be entirely integrated into the packaging line.

Markem-Imaje 2200 Series

Able to print and apply at over 150 packs per minute, regardless of code complexity, we offer a wide range of interchangeable applicators for each of your applications, minimizing line changes, including AI-enhanced and automation-enabling options.

View Markem-Imaje 2200

Markem-Imaje SmartDate ® X30

Designed for low- to medium-speed production. The SmartDate ® X30 is a robust one-box solution that can easily be installed on your line or integrated by OEMs. It is both easy to use and offers unmatched reliability.

View Markem-Imaje SmartDate ® X30Markem-Imaje SmartDate ® X45

Designed for easy integration into medium-duty equipment, the SmartDate ® X45 prints at up to 600 mm per second, allowing for 220 printed packs per minute at 300 dpi. It features a 10.1” color user interface that simplifies tracking OEE data.

View Markem-Imaje SmartDate ® X45Markem-Imaje SmartDate ® X65

Designed for direct integration into heavy-duty equipment running demanding applications, the SmartDate ® X65 is ideal for ultrafast, high-resolution. This combined overprinter can offer intermittent or continuous configuration in one system.

View Markem-Imaje SmartDate ® X65

Markem-Imaje 1050

Designed for low-volume production printing, a reliable, easy-to-use coder that uses low-maintenance, snap-in, and snap-out cartridges.

View Markem-Imaje 1050

Markem-Imaje 9330

Designed for light to medium-duty production lines. The cost-efficient 9330 will cover all your basic extrusion product coding needs and is available with an extrusion-dedicated yellow semi-pigmented permanent and MEK-free ink.

View Markem-Imaje 9330Markem-Imaje 9750

Designed for medium-duty production lines. Our next generation 9750 range delivers clear, customizable, traceable black or colored codes, including 2D codes (QR and DotCodes).

Markem-Imaje 9750 Plus

Designed for large production fleets, the 9750+ with its revolutionary, polyvalent ink circuit performs both standard marking or pigmented contrast printing. It is highly robust and has features that support your ESG and Industry 4.0 objectives.

View Markem-Imaje 9750+

CIJ inks

Markem-Imaje offers a universal MEK-free black ink for printing on shrink film, which is compliant with accidental food contact.

SmartLase ® C350

Designed for medium to high-speed intermittent or continuous lines, the SmartLase ® C350 30-watt CO2 laser delivers permanent, crisp, clear and traceable codes on shrink wrap film, 30% faster than other lasers, at up to 150,000 products per hour.

View SmartLase® C350SmartLase ® C600

Designed for high-speed applications and for the most challenging Industry 4.0 environments. Our most advanced CO2 laser coder, the SmartLase ® C600 delivers superb code quality and more power, even with 1D and 2D codes.

View SmartLase® C600SmartLase ® F250

Designed for high-speed applications, exceling on high-density plastic materials, the F250 20-watt fiber laser offers superb code quality, even with the increasing code complexity associated with 1D and 2D codes.

View SmartLase® F250SmartLase ® UV500

Designed for high-density materials like wraps and films, our SmartLase® UV500 5-watt UV laser delivers the most precise, high-quality coding with the added benefit of minimal heat transfer.

View SmartLase® UV500

Markem-Imaje offers a range of compliant solutions for your printing on shrink wrap film for secondary packaging requirements in P&A, TIJ, LCIJ, and valvejet printing. All provide high-quality and cost-effective coding for printing on shrink film for cases and corrugate.

Markem-Imaje 2200

Able to print and apply at over 150 packs per minute, regardless of code complexity, we offer a wide range of interchangeable applicators for each of your applications, minimizing line changes, including AI-enhanced and automation-enabling options.

View Markem-Imaje 2200Markem-Imaje 2200 Pallet

The 2200 Pallet system can be easily integrated onto any production line, providing outstanding print quality and fully compliant labeling. Delivering 1 or 2-side labeling at speeds of up to 120 pallets per hour.

View Markem-Imaje 2200 Pallet

Markem-Imaje 1200

Designed to be compact and portable, the low-maintenance, easy-to-operate 1200 produces high-resolution text, logos, graphics, and 100% scannable barcodes at up to 600 dpi.

View Markem-Imaje 1200

Markem-Imaje 5800

Easy to operate and maintain, the Touch Dry® Markem Imaje 5800 large character printer produces high-resolution 100% readable text, logos and GS1-1D and 2D barcodes, ideal for compliance objectives.

View Markem-Imaje 5800Markem-Imaje 5940 G

The 5940 G sets the standard of coding quality, compliance, operational efficiency and reduced TCO, allowing you to print C grade barcodes, text and graphics. With 75% larger ink container than most competitors and 43% less operator intervention with on-the-fly ink refills.

View Markem-Imaje 5940 G

Markem-Imaje 4500

Designed for easy installation and operation, the 4500 large character offers single-sided, drop-on-demand lower resolution, and cost-effective printing up to 56mm high. Its highly responsive color touch screen makes daily operations immediate and simple.

View Markem-Imaje 4500Markem-Imaje 4700

Designed with two printheads to allow one or doubled-sided efficient and robust case coding, the 4700 can create a code with up to 114 mm characters and features a 20-liter capacity ink cannister for maximized uptime.

View Markem-Imaje 4700

Simply leave your email address in the box on this page to be contacted by one of our experts who can provide detailed information to help you find the best solution for your printing on shrink wrap film application, whether it is for primary, secondary or pallet packaging.

By completing this questionnaire, you agree to the processing of your personal data by Markem-Imaje. You can consult our data protection policy at https://www.markem-imaje.com/privacy.

You may also be interested in discovering more about...

For secondary and tertiary packaging coding see our dedicated box offers

Find all our paperboard and box printing offers for secondary and tertiary packaging:

Corrugated case marking offers.

Consumables and supplies

Find our genuine CIJ, DOD, TIJ, and Touch Dry Hot melt inks adapted to each marking need:

Inks and additives.

Find the thermal printing ribbon products:

Ribbons and labels.

Software

Find options to digitalize your packaging operations easily:

CoLOS software solutions.

Solutions

Find secondary packaging coding options for boxed extruded material, cables, and wires:

Late-stage box printing.

Find our unique in-the-market solutions that help you throughout the supply chain:

End-to-End Supply Chain Solutions.

Find our Packaging Intelligence Solution to enhance and achieve traceability:

Traceability solutions.

Find industry hot topics that benefit from using 2D barcodes for connected products:

Connected and compliant 2D barcodes.

Find out how CoLOS can increase your pallet labeling process:

SSCC Pallet Labeling.

Find real-world case studies demonstrating the benefits that GS1-128 brings:

Compliant GS1-128 barcodes.